KAVAN ESCs - Instruction manual/fr: Difference between revisions

(Created page with "Les gaz sont maintenant calibrés, et votre contrôleur est prêt à fonctionner.") |

(Created page with "=== Procédure normale de démarrage du contrôleur ===") |

||

| Line 134: | Line 134: | ||

Les gaz sont maintenant calibrés, et votre contrôleur est prêt à fonctionner. | Les gaz sont maintenant calibrés, et votre contrôleur est prêt à fonctionner. | ||

< | <span id="Normal_ESC_start-up_procedure"></span> | ||

=== | === Procédure normale de démarrage du contrôleur === | ||

<div lang="en" dir="ltr" class="mw-content-ltr"> | <div lang="en" dir="ltr" class="mw-content-ltr"> | ||

Revision as of 07:32, 28 January 2025

Introduction

Contrôleurs électroniques programmables pour moteurs brushless.

Félicitations pour l’achat de votre variateur électronique KAVAN Line pour moteurs brushless. La gamme KAVAN couvre presque l’intégralité des avions électriques utilisés par les modélistes amateurs. Tous les contrôleurs peuvent être rapidement programmés via votre émetteur, ou encore plus facilement avec la carte de programmation KAVAN proposée en option (KAV32.42015).

Fonctions programmables

- Réglage du frein (utiliser le frein uniquement pour l’utilisation d’hélices repliables)

- Type de batterie (LiPo ou NiCd/NiMH)

- Type de coupure de basse tension (réduction de puissance ou arrêt immédiat)

- Réglage de la coupure de basse tension

- Démarrages avec accélération douce (lors de l’utilisation de boîte de vitesses et hélicoptères)

- Réglages du timing (pour améliorer l'efficacité et la fluidité du contrôleur)

Caractéristiques techniques

| Type de BEC | Courant (Cont./Pointe) | Tension d’entrée (nbre de cellules) | Poids | BEC (tension/courant) | Dimensions | |

| KAVAN R–6B | *BEC | 6/8 A | 2S LiPo | 5.5 g | 5 V/0.8 A | 32×12×4.5 mm |

| KAVAN R–12B | *BEC | 12/15 A | 2–3S LiPo | 9 g | 5 V/1 A | 38×18×6 mm |

| KAVAN R–15B | *BEC | 15/20 A | 2–3S LiPo | 16.5 g | 5 V/2 A | 48×22.5×6 mm |

| KAVAN R–20B | *BEC | 20/25 A | 2–3S LiPo | 19 g | 5 V/2 A | 42×25×8 mm |

| KAVAN R–30B | *BEC | 30/40 A | 2–3S LiPo | 37 g | 5 V/2 A | 68×25×8 mm |

| KAVAN R–40B | *BEC | 40/55 A | 2–3S LiPo | 39 g | 5 V/3 A | 68×25×8 mm |

| KAVAN R–40SB | **SBEC | 40/55 A | 2–4S LiPo | 43 g | 5 V/3 A | 65×25×12 mm |

| KAVAN R–50SB | **SBEC | 50/65 A | 2–4S LiPo | 41 g | 5 V/7 A | 65×29×10 mm |

| KAVAN R–60SB | **SBEC | 60/80 A | 3–6S LiPo | 63 g | 5 V/7 A | 77×35×14 mm |

| KAVAN R–80SB | **SBEC | 80/100 A | 3–6S LiPo | 82 g | 5 V/7 A | 86×38×12 mm |

*) BEC – BEC linéaire

**) SBEC – BEC à découpage puissant

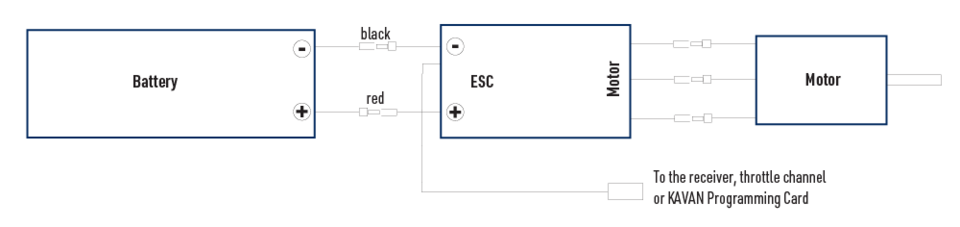

Branchement du contrôleur KAVAN

Le contrôleur de vitesse peut être branché au moteur par soudure directe ou à l’aide de connecteurs de haute qualité. Utilisez toujours des connecteurs neufs, qui doivent être soigneusement soudés aux câbles et isolés avec une gaine thermorétractable. Utilisez également des connecteurs de haute qualité pour brancher le contrôleur à la batterie de propulsion - Connecteurs plaqués or 2mm (KAV36.119 ou KAV36.120) pour des courants jusqu'à 20A; Connecteurs plaqués or 3,5mm (KAV36.122), 4 mm (KAV36.126) ou DEAN-T® (KAV36.108) pour des courants jusqu'à 60A et connecteurs 6mm (KAV36.128) pour des courants jusqu'à 80A. La longueur des câbles de la batterie ne doit pas dépasser 15cm (6 pouces).

Branchez le câble du connecteur servo UNI du contrôleur à la sortie des gaz de votre récepteur. Les contrôleurs équipés d’un stabilisateur de tension BEC ou SBEC alimentent votre récepteur et vos servos à partir de la batterie de propulsion.

Schéma de câblage des contrôleurs KAVAN

Veuillez noter qu'une polarité incorrecte ou un court-circuit endommagera le contrôleur (ESC). Il est donc de votre responsabilité de vérifier attentivement tous les connecteurs pour assurer une polarité et un branchement corrects AVANT de brancher la batterie pour la première fois.

Mise sous tension pour la première fois et calibration automatique des gaz

Le contrôleur KAVAN dispose d'une fonction de calibration automatique des gaz pour garantir une réponse fluide et une précision optimale sur toute la plage des gaz de votre émetteur. Cette étape doit être réalisée une seule fois afin que le contrôleur puisse "apprendre et mémoriser" le signal de sortie des gaz de votre émetteur. Elle doit être répétée uniquement si vous changez d’émetteur.

- Mettez sous tension l'émetteur et placez le manche des gaz en position haute.

- Branchez la batterie au contrôleur (ESC) et attendez environ 2 secondes.

- Un signal sonore "Bip–Bip–" doit être émis, confirmant que le point haut de la plage des gaz a été enregistré.

- Ramenez le manche des gaz en position basse. Plusieurs signaux sonores "Bip–" doivent être émis pour indiquer le nombre de cellules de la batterie.

- Un signal sonore long "Bip–" doit être émis, confirmant que le point bas de la plage des gaz a été correctement enregistré.

Les gaz sont maintenant calibrés, et votre contrôleur est prêt à fonctionner.

Procédure normale de démarrage du contrôleur

- Move the throttle stick to the bottom position and then switch on the transmitter.

- Connect the battery pack to ESC. A special tone like "123" means the power supply is OK.

- Several "beep–" tones should be emitted to present the amount of lithium battery cells.

- When the self–test is finished, a long "beep–" tone should be emitted.

- Slowly move the throttle stick up. The prop should start rotating clockwise (looking from the cockpit of the plane). If it spins in the opposite direction, pull the throttle stick back, disconnect the flight battery and swap any two of the three cables between the motor and the ESC. Then re-check again.

Protection function

- Startup failure protection: If the motor fails to start within 2 seconds of throttle application, the ESC will cut–off the output power. In this case, the throttle stick MUST be moved to the bottom again to restart the motor. (Such a situation happens in the following cases: the connection between ESC and the motor is not reliable, the propeller or the motor is blocked, the gearbox is damaged, etc.).

- Overheat protection: When the temperature of the ESC is over about 110°C, the ESC will reduce the output power.

- Throttle signal loss protection: The ESC will reduce the output power if the throttle signal is lost for 1 second. Further loss for 2 seconds will cause the output to be cut off completely.

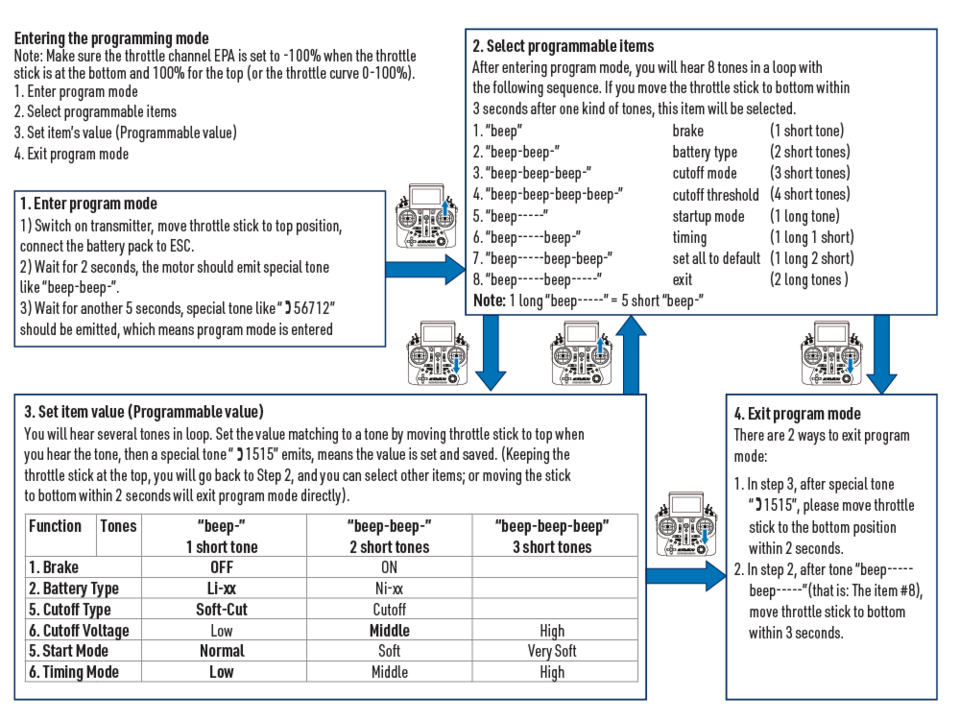

Programmable functions of the KAVAN ESC

- Brake: ON/OFF

ON – Sets the propeller to the brake position when the throttle stick is at the minimum position (recommended for folding props).

OFF – Sets the propeller to freewheel when the throttle stick is at the minimum position. - Battery type: LiPo or NiCd/NiMH

- Low voltage cutoff type: Reduce power/hard cutoff

Reduce power – ESC reduces motor power when the preset Low voltage protection threshold value is reached.

Hard cutoff – ESC instantly cuts motor power off when the preset low voltage protection threshold value is reached. - Low voltage protection threshold: Low/Medium/High

For Li-xx packs – the battery cell number is calculated automatically. The Low/Middle/High cutoff voltage for each cell is: 2.85 V/3.15 V/3.3 V. For example: For a 3S LiPo, when the "Middle" cutoff threshold is set, the cut–off voltage will be: 3.15×3 = 9.45 V.

For Ni–xx packs – Low/Medium/High cutoff voltages are 0 %/50 %/65 % of the startup voltage (i.e. the initial voltage of battery pack), and 0 % means the Low voltage cut–off function is disabled. For example: For a 6-cell NiMH battery, the fully charged voltage is 1.44×6 = 8.64 V, when the "Middle" cutoff threshold is set, the cutoff voltage will be: 8.64×50 % = 4.32 V. - Soft acceleration start–up: Normal/Soft/Very soft

Normal mode is suitable for fixed–wing aircraft. Soft or Very soft modes are suitable for helicopters. The initial acceleration of the Soft and Very soft modes is slower. It takes 1.5 seconds for the Soft startup or 3 seconds for the Very soft startup from initial throttle advance to full throttle. If the throttle is completely closed (throttle stick moved to bottom position) and opened again (throttle stick moved to top position) within 3 seconds after the first startup, the re–startup will be temporarily changed to normal mode to get rid of the chance of a crash caused by slow throttle response. This special design is suitable for aerobatic flight when quick throttle response is needed. - Timing set–up: Low/Middle/High

Low (3.75°) – setting for most 2 pole motors.

Middle (15°) - setting for motors with 6 or more poles.

High (26.25°) - setting for motors with 12 or more poles, out runners.

In most cases, middle or low timing works well for all types of motors. However, for high efficiency, we recommend the low timing setting for 2 pole motors (generally, in–runners) and middle timing for 6 poles and above (generally all outrunners). For higher speeds, high timing can be set. Some motors require different timing setups, therefore we suggest you follow the manufacturer-recommended setup.

Using the KAVAN programming card (optional)

You can also use the optional KAVAN programming card (KAV32.42015) to program your desired functions. The use of the KAVAN card is very simple and convenient: the programmable functions and their values are to be set with a couple of buttons. Simply set all the functions on the card to the desired values and load the settings to the ESC. Programming your ESC with the KAVAN Card is a breeze.

Troubleshooting

| Trouble | Possible reason | Solution |

|---|---|---|

| After powering on, the motor does not work and no sound is emitted. | The connection between the battery pack and ESC is not correct. | Check the power connection. Replace the connector. |

| After powering on, the motor does not work, such an alert tone is emitted: "beep–beep–, beep–beep–, beep–beep–" (Every "beep–beep–" has a time interval of about 1 second). | Input voltage is abnormal, too high or too low. | Check the voltage of the battery pack. |

| After powering on, the motor does not work, such an alert tone is emitted: "beep–, beep–, beep–" (Every "beep–" has a time interval of about 2 seconds). | Throttle signal is irregular. | Check the receiver and transmitter. Check the cable of the throttle channel. |

| After powering on, the motor does not work, such an alert tone is emitted: "beep–, beep–, beep–" (Every "beep–" has a time interval of about 0.25 seconds). | The throttle stick is not in the bottom (lowest) position. | Move the throttle stick to the bottom position. |

| After powering on, the motor does not work, a special tone "56712" is emitted after a 2-beep tone (beep–beep–). | The direction of the throttle channel is reversed, so the ESC has entered the program mode. | Set the direction of the throttle channel correctly. |

| The motor runs in the opposite direction. | The direction. The connection between ESC and the motor needs to be changed. | Swap any two wire connections between ESC and motor. |

Safety precautions

- Do not install the propeller (fixed-wing) or drive pinion (helicopter) on the motor when you test the ESC and motor for the first time to verify the correct settings on your radio. Only install your propeller (plane) or pinion (helicopter) after you have confirmed that the settings on your radio are correct.

- Never use ruptured or punctured battery cells.

- Never use battery packs that are known to overheat.

- Never short circuit battery or motor terminals.

- Always use proper insulation material for cable insulation.

- Always use proper cable connectors.

- Do not exceed the number of cells or servos specified for the ESC.

- Wrong battery polarity will damage the ESC and void the warranty.

- Install the ESC in a suitable location with adequate ventilation for cooling. This ESC has a built-in over-temperature cutoff protection feature that will immediately cut power to the motor once the ESC temperature exceeds the 230 °F/ 110 °C temperature limit.

- Use only batteries supported by the ESC and ensure the correct polarity before connecting.

- Switch your transmitter ON first and ensure the throttle stick is in the minimum position before connecting the battery pack.

- Never switch your transmitter OFF while the battery is connected to your ESC.

- Only connect your battery pack just before flying and do not leave your battery pack connected after flying.

- Handle your model with extreme care once the battery pack is connected and keep away from the propeller at all times. Never stand in–line or directly in front of any rotating parts.

- Do not immerse the ESC under water, do not allow it to get wet while powered up.

- Always fly at a designated flying site and follow the rules and guidelines set by your modeller’s club.

Recycling and Waste Disposal Note (European Union)

Electrical/electronic equipment marked with the crossed-out waste bin symbol must not be discarded in the domestic waste; it should be disposed of via the appropriate specialised disposal system. In the countries of the EU (European Union) electrical/electronic devices must not be discarded via the normal domestic waste system (WEEE - Waste of Electrical and Electronic Equipment, Directive 2012/19/EU). You can take your unwanted equipment to your nearest public collection point or recycling centre, where it will be disposed of in the proper manner at no charge to you. By disposing of your old equipment in a responsible manner you make an important contribution to the safeguarding of the environment!

EU Declaration of Conformity

Hereby KAVAN Europe s.r.o. declares that these KAVAN line brushless electronic speed controllers are in compliance with the essential requirements as laid down in the EU directive(s) concerning electromagnetic compatibility. The full text of the EU Declaration of Conformity is available at www.kavanrc.com/doc/

Guarantee

The KAVAN Europe s.r.o. products are covered by a guarantee that fulfils the currently valid legal requirements in your country. If you wish to make a claim under guarantee, please contact the retailer from whom you first purchased the equipment. The guarantee does not cover faults caused in the following ways: crashes, improper use, incorrect connection, reversed polarity, maintenance work carried out late, incorrectly or not at all, or by unauthorised personnel, use of other than genuine KAVAN Europe s.r.o. accessories, modifications or repairs which were not carried out by KAVAN Europe s.r.o. or an authorised KAVAN Europe s.r.o., accidental or deliberate damage, defects caused by normal wear and tear, operation outside the Specification, or in conjunction with equipment made by other manufacturers. Please be sure to read the appropriate information sheets in the product documentation!