KAVAN Smart PRO SBEC ESCs - Manuel d'instruction

Introduction

Contrôleurs électroniques programmable intelligents pour moteurs brushless

Félicitations pour l'achat de ce contrôleur de vitesse électronique pour moteur brushless de la gamme KAVAN Smart PRO. La gamme de produits KAVAN Smart PRO comporte des contrôleurs de moteur brushless avancés, à utiliser exclusivement dans les avions modèles R/C. Avec une télémétrie intégrée et diverses options de configuration utilisateur, les contrôleurs offrent une haute efficacité, un poids léger et un contrôle moteur précis. Le puissant BEC intégré offre un courant de sortie continu allant jusqu'à 15A et est adapté même aux applications les plus exigeantes. Les performances complètes du circuit BEC sont disponibles à toute tension de batterie dans les spécifications du contrôleur (6–51V).

Caractéristiques

- Petite taille combinée à une haute puissance pour le contrôle du moteur.

- Le circuit de commutation BEC haute performance offre un courant continu allant jusqu'à 15A (30A max). Une protection contre les surintensités et les surchauffes est incluse.

- Réglage de la tension BEC par incréments de 0,1V.

- Protection contre les surtensions et les sous-tensions, protection contre les surchauffes et protection contre l'arrêt soudain du moteur.

- Limiteur de courant réglable.

- Mode hélicoptère/governor rapide et précis avec de nombreuses options de réglage.

- Arrêt de sécurité du moteur en cas de perte d'impulsion des gaz.

- Accélération, timing, frein électromagnétique, inversion du moteur configurables, etc.

- Faible bruit acoustique grâce à la commutation haute fréquence.

- Télémétrie automatique : FPort, configurable via script Lua. Firmware alternatif Duplex EX, Hott, MSB, P²Bus, S.Bus2, SRXL2.

- Télémétrie (selon le système R/C) : tension, courant, puissance, capacité, température, vitesse, énergie.

- Les valeurs de télémétrie minimales/maximales sont enregistrées.

- Configuration via un émetteur, un logiciel PC MAV Manager ou un terminal externe (JETIBOX/SMART-BOX).

- Mise à jour du firmware via interface USB.

- Langues : CZ/DE/EN/FR/IT.

| 45LV | 55HV | 65HV | 85HV | 115HV | 115HV ACRO | 145HV | 155 | |

|---|---|---|---|---|---|---|---|---|

| Dimensions (mm) | 62×27×10 | 75×29.5×10 | 75×29.5×12 | 80×30×13.5 | 88×32×14 | 88×32×20 | 74×53×31 | 88×32×14 |

| Poids incl. câbles (g) | 50 | 63 | 68 | 81 | 100 | 125 | 190 | 100 |

| Courant continu (A) | 40* | 50* | 60* | 80* | 110* | 110* | 140* | 150* |

| Courant de crête (A/2s) | 90* | 80* | 100* | 120* | 170* | 170* | 200* | 200* |

| Tension d'alimentation (V) | 6–26 | 6–51 | 6–51 | 6–51 | 6–51 | 6–51 | 10–51 | 6–27 |

| Cellules LiPo | 2–6 | 2–12 | 2–12 | 2–12 | 2–12 | 2–12 | 4–12 | 2–6 |

| Cellules LiFe | 3–14 | 3–14 | 3–14 | 3–14 | 3–14 | 4–14 | 3–7 | |

| Câbles batterie/moteur (mm²) | 2.5 / 2.5 | 2.5 / 2.5 | 2.5 / 2.5 | 4 / 2.5 | 4 / 4 | 4 / 4 | 6 / 4 | 6 / 4 |

| Circuit antispark | Non | |||||||

| Connecteurs recommandés | XT60 (60A) | XT60 (60A) | XT60 (60A) | G4 (75A), XT90 (90A) | G5.5, XT90 (90A) | G5.5, XT90 (90A) | G5.5 (150A) | G5.5 (150A) |

| Plage de température (°C) | (-10)–110 | |||||||

| PWM frequency (kHz) | 20 | |||||||

| Courant de fonctionnement (mA) | 60 | |||||||

| Courant en veille (mA) | 4 | |||||||

| Positionnement de l'hélice | Non | Avec capteur Hall supplémentaire | ||||||

| Télémétrie | FrSky FPort, JETI Duplex EX, Multiplex MSB, Futaba S.Bus2, Graupner Hott, PowerBox P²Bus, Spektrum SRXL2™ | |||||||

| LED d'état | Oui | |||||||

| Frein actif (roue libre) | Oui | |||||||

| Courant continu de sortie BEC (A) | 10* | 12* | 15* | |||||

| Courant de crête BEC (A/2s) | 20* | 25* | 30* | |||||

| Réglage de tension BEC (V) | 5.5–8.4 (par pas de 0.1V) | |||||||

| Isolation optique | Non | |||||||

| Vitesse maximale (eRPM) | > 300 000 (moteur bipolaire) | |||||||

| Tension de l'interrupteur externe (V) | 10 (environ) | |||||||

| Courant de l'interrupteur externe (mA) | 30 (max.) | |||||||

*) Les valeurs spécifiées sont valables si un flux d'air continu suffisant est fourni.

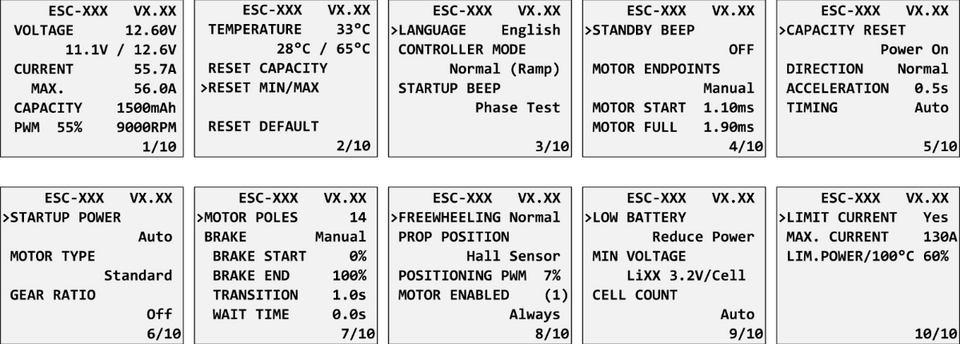

Installation

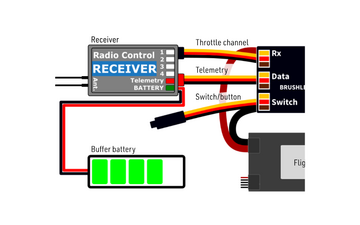

Fasten the controller in your model using hook-and-loop or double-sided adhesive tape. Connect the motor and receiver according to the schematic below. You may connect the motor cables in arbitrary order, as changing direction is done by exchanging any of the two cables (alternatively also by the “Direction” parameter in the configuration). Turn on the transmitter. Now you can plug in the main flight pack and turn on the speed controller with the receiver attached.

{{Note|type=error|text=Avertissement : Utilisez toujours des connecteurs neufs et de haute qualité et assurez-vous que les câbles sont parfaitement soudés. Toute possibilité de perte de connexion pendant le fonctionnement du moteur représente un risque d'endommager vos composants électroniques.

Si vous démarrez le contrôleur pour la première fois ou apportez des modifications importantes à la configuration, assurez-vous que l'hélice est retirée de l'arbre du moteur.

Débranchez toujours les batteries après la fin de la session de vol. Même si le contrôleur de vitesse est éteint par l'interrupteur, il consomme encore un petit courant. Cela pourrait entraîner une décharge complète de la batterie en quelques jours ou semaines.

Mode du contrôleur

Il est possible de choisir parmi plusieurs modes de contrôleur de base :

- Normal (rampé) - le temps d'accélération préconfiguré est toujours appliqué lors de l'accélération. C'est le mode par défaut pour une utilisation principale.

- Mode rapide - l'accélération préconfigurée est appliquée uniquement lors de l'accélération à partir de zéro tour. Après cela, un délai minimum possible est utilisé (0,2 s pour une réponse de zéro à plein régime).

- Normal avec inversion - se comporte de manière similaire au mode Normal. De plus, vous pouvez choisir une voie inversée des gaz qui contrôlera le sens de rotation du moteur pendant le vol.

- Heli/Governor - contrôle rapide et précis de la vitesse constante avec de nombreux paramètres ajustables.

Signal d’entrée des gaz

Le contrôleur attend des impulsions positives du récepteur avec un taux de rafraîchissement maximal pouvant atteindre 400Hz. Par défaut, avec des points de terminaison automatiques sélectionnés, le contrôleur fonctionnera avec la grande majorité des systèmes R/C.

Dans ce cas, une impulsion de signal de gaz minimale est chargée après le démarrage. La puissance maximale est ensuite ajustée dynamiquement lorsque vous donnez pour la première fois les gaz à fond.

Si vous avez besoin de points exacts sur le manche de votre émetteur, où le moteur démarre et où les gaz sont à fond, vous pouvez également configurer des points de terminaison manuels.

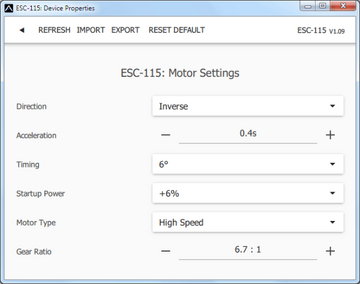

Réglages du moteur

Il est possible de configurer de nombreux paramètres du moteur, y compris l'accélération, le timing, le rapport de transmission du moteur ou le nombre de pôles. Le rapport de transmission et le nombre de pôles sont importants pour que la télémétrie mesure correctement la vitesse du moteur.

L'accélération influence la réponse du moteur sur la voie des gaz. En diminuant la valeur de l'accélération, la réponse du moteur devient plus rapide, procurant une sensation de contrôle accrue. Cependant, le moteur consomme plus de courant et le contrôleur génère plus de chaleur. Nous recommandons l'accélération par défaut de 1,0s pour la majorité des types de modèles, y compris les planeurs électriques, les modèles réduits et les EDF. Pour le vol acrobatique 3D, vous pouvez réduire à 0,5s, voire moins (avec précaution). Pour la réponse moteur la plus rapide, vous pouvez également activer le "mode contrôleur rapide" dans les Paramètres Généraux.

Le timing est défini par le type de moteur et est généralement recommandé par le fabricant du moteur. Il influence également la puissance du moteur et la consommation de courant. Un timing plus élevé peut augmenter la puissance du moteur, mais il faut veiller à ne pas surcharger le système.

- Timing automatique : le timing est ajusté en continu par l'algorithme interne. C'est une solution universelle compatible avec la plupart des types de moteurs.

- Timing de 0 à 10° : recommandé pour les inrunners, c'est-à-dire les moteurs avec aimants internes.

- Timing de 15 à 20° : recommandé pour la plupart des outrunners (moteurs avec boîtier rotatif). Il offre une bonne combinaison de puissance et d'efficacité.

- Timing de 25 à 30° : les moteurs à couple élevé avec de nombreux pôles nécessitent le timing le plus élevé.

Le type de moteur ne doit être modifié que dans certains cas spécifiques où l'application l'exige.

Il y a trois options disponibles :

- Type de moteur "Standard" - recommandé pour la plupart des types et applications (par défaut).

- Type de moteur "Couple élevé" - si vous rencontrez des problèmes de synchronisation du moteur lors d'accélérations rapides, utilisez ce mode. Conditions préalables : grand moteur outrunner avec plus de 20 pôles, hélice lourde, pics de courant élevés. Nous recommandons également d'augmenter le timing à plus de 20°.

- Type de moteur "Haute vitesse" - utilisez ce mode si votre unité de propulsion dépasse 250 000 eRPM (tours par minute calculés pour un moteur à 2 pôles).

La puissance de démarrage influence les premiers tours du moteur. Si vous n'êtes pas satisfait du mode automatique, vous pouvez régler le démarrage du moteur pour qu'il soit plus agressif (valeurs positives) ou aussi doux que possible (valeurs négatives).

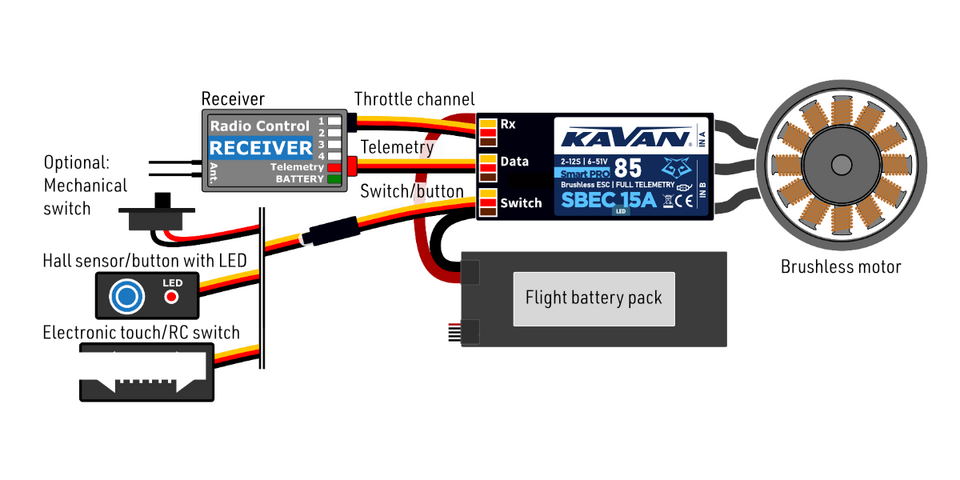

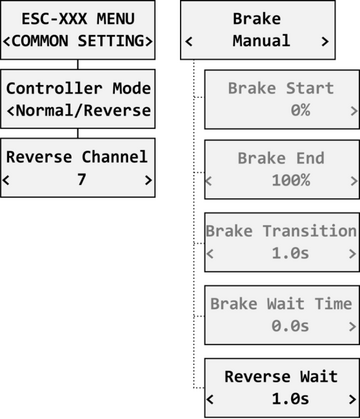

Configuration des freins

Le frein électromagnétique est une caractéristique standard de tous les ESC utilisés dans les modèles de planeurs électriques. Le contrôleur KAVAN Smart PRO propose plusieurs paramètres supplémentaires pour affiner la fonction de freinage. Vous pouvez utiliser l'un des paramètres de freinage préconfigurés ou spécifier tous les paramètres selon vos souhaits.

Options de freinage :

- Off : L'hélice tourne librement sans être freinée

- Soft : Transition de zéro à la force de freinage maximale en 1,0 s.

- Medium : Transition à la force de freinage maximale en 0,7 s.

- Hard : Transition de 50% à 100% de la force de freinage en 0,5 s.

- Manuel : Vous pouvez spécifier tous les paramètres de freinage manuellement :

- Puissance de départ (début du freinage) - force de freinage appliquée dès le premier instant du freinage.

- Puissance de fin (fin du freinage) - force de freinage appliquée après le temps de transition (généralement la force de freinage complète qui arrête complètement le moteur).

- Transition - le temps entre la puissance de départ du frein et la puissance de fin du frein. Pendant ce temps, la force de freinage passe continuellement de la puissance de départ à la puissance de fin.

- Temps d'attente - le temps entre l'arrêt du moteur et l'application du frein. Pendant ce temps, le moteur tourne librement sans puissance.

Exemple : frein moteur avec les paramètres suivants : départ du frein = 50%, fin du frein = 100%, rampe = 0,5s, temps d'attente = 0,3s.

Tension et réglages du bec

Dans le menu des Paramètres Communs, vous pouvez modifier la tension du BEC très précisément par paliers de 0,1V. Le contrôleur contient un BEC très puissant qui peut fournir jusqu'à 15A de courant continu. Cependant, en cas de configuration haute puissance, un refroidissement adéquat doit être assuré. Il est recommandé de brancher les câbles de Télémétrie et des Gaz au récepteur pour garantir un débit de courant élevé.

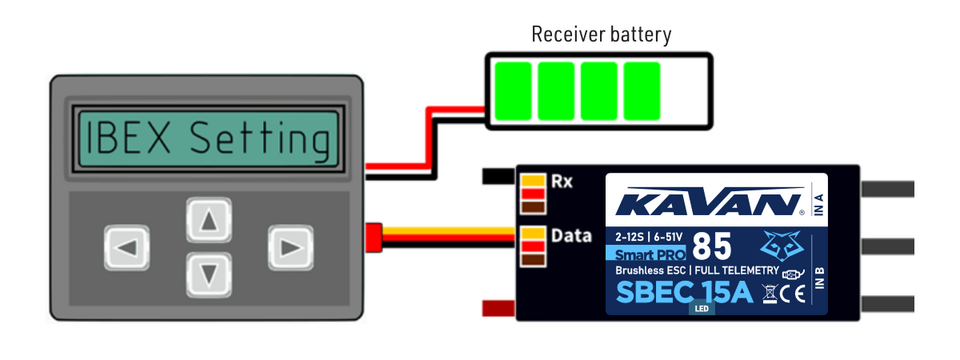

Batterie de secours

Si vous avez besoin d'une petite batterie tampon pour couvrir les pics de tension des servos branchés, vous pouvez spécifier sa présence dans le menu des Paramètres Communs - Batterie de secours. Après avoir réglé le type de batterie, il est nécessaire de retirer toutes les sources d'alimentation du contrôleur, puis de les reconnecter. Options possibles :

- "Non" (par défaut) - La batterie tampon n'est pas présente et la tension du BEC est réglée en fonction de la valeur définie dans la configuration. Aucune alimentation externe ne doit être branchée côté récepteur, sinon le BEC ne s'allumera pas.

- "2S LiPo 8.4V" - Une alimentation externe avec une tension maximale de 8,4V est attendue côté récepteur (voir l'image). Le contrôleur ne s'initialisera pas si la tension de la batterie de secours est hors limites (ou non branchée). La tension du BEC sera automatiquement réglée en fonction de la batterie de secours pour éviter les courants incontrôlés.

- "2S LiFe 7.2V" - Une alimentation externe avec une tension maximale de 7,2V est attendue côté récepteur. Le comportement est similaire à celui du 2S LiPo.

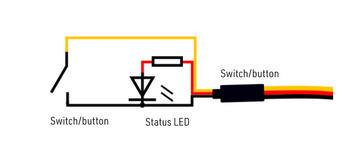

External switch

The KAVAN Smart PRO ESC allows you to install an external switch if needed. By default, the switch is not present so the speed controller/BEC turns on immediately after connecting the flight battery.

You can specify the type of switching element in the Common Setting – Switch Type:

- Mechanical (default) - the switch shorts the yellow (signal) and brown (ground) wires of the Switch/Button cable. An inverted logic is used, so that the ESC stays turned on if the switch is left open.

- Button/Hall - the first long press turns on the ESC; the second long press turns it off. The LED indicates an on/off state and blinks if the magnet (or button press) is detected. The Hall sensor can be bought as an ESC accessory.

- Electronic - allows you to install an external electronic switch (Touch Switch, RC Switch etc.). In this case, the switching device is always powered and the logic level of the signal wire specifies the on/off state to the controller.

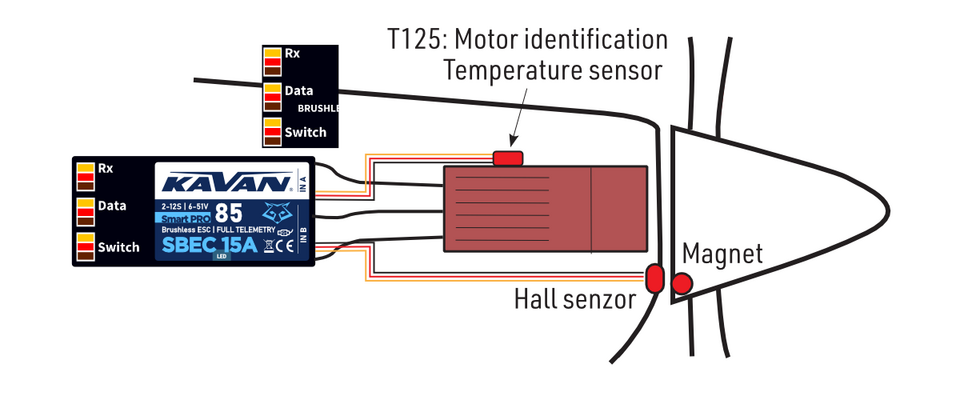

Propeller positioning

The positioning feature allows moving the motor/propeller to the exact position required for a safe landing, or which is just comfortable for further flying. With just a few external components (a Hall sensor and a small magnet) you can enable this feature and prevent the risk of damaging your propeller during landing. The magnet needs to be properly fixed to the rotating part (either the motor or the propeller), and the Hall sensor has to be located in the fuselage so that the magnet matches the Hall sensor at the target propeller position. After enabling the positioning feature in the menu (Prop Position = Hall Sensor), set also the Positioning PWM, so that the motor spins slowly but smoothly. You may also change the duration of the actively held motor position (Position Hold Time) which is applied after the correct position is found. The position-hold feature is useful in the case of a retractable engine since it doesn’t allow the propeller to be moved while retracting.

Connect the Hall sensor of the propeller positioning function to the IN-B port of the controller.

Motor identification

Some motor brands contain an integrated temperature sensor compatible with the KAVAN Smart PRO speed controller. This sensor (T125-ID) might be used as a standalone telemetry sensor with Duplex/Hott/S.Bus2 telemetry support. Alternatively, the sensor can be directly connected to the Input port "A" of the controller (see the picture above). From this moment on, the KAVAN Smart PRO controller will know the basic motor parameters (minimum acceleration, recommended timing, gear ratio, number of poles…) and motor temperature as well. Some parameters are adjusted automatically (gear ratio, poles), and the other settings are configured after resetting the controller to factory defaults. Connect the motor-identification sensor into the IN-A port of the controller.

Active freewheeling

"Active freewheeling" or "Active braking" is a feature of the speed controller that reduces heat generated by the ESC during partial load operation. This mode is useful for aerobatic pilots who want not only fast acceleration but also rapid deceleration. The motor follows throttle stick input in both ways and the pilot feels more "locked-in".

Current limiter

The current limiter is a part of safety controller features. It doesn’t stop the motor but rather continuously monitors the immediate current consumption and adjusts the motor power. You can enable this feature, specify the maximum allowed current and the ESC will reduce the motor power immediately as soon as the current threshold is exceeded. After the current returns back to the safe level, the motor power is restored.

Battery protection

The integrated battery protection is based on undervoltage detection and reducing motor power, alternatively shutting down the motor completely. You can freely set the number of cells (or leave automatic detection) and low voltage threshold per cell. Supported battery types are NiXX (1.2 V), LiFe (3.6 V max) and LiIo/LiPo (4.2 V max).

Status codes

The status codes are shown on the screen (JETIBOX/SMART-BOX) if any kind of error condition occurs. If any status code is set, the red LED continuously flashes.

Available status codes:

- Low Voltage (UL): the battery voltage got below the threshold specified in the battery protection menu and the controller either reduced the maximum power or shut down the motor completely.

- High voltage (UH): in case you use a weak battery or wall power supply, the voltage might rise above the initial level during braking. In such a case, the alarm is set and all braking functions are disabled.

- High current (IH): the current got higher than the maximum peak current defined in the product specification (120 A for KAVAN Smart PRO 85).

- High temperature (T100, T110, T120): the temperature got above the safety threshold level. The numerical value specifies the maximum detected temperature and safety protocol which has been applied.

- Commutation error (COM): a synchronization error has been detected during the motor operation. It usually occurs when the motor stops abruptly, or in case of very fast acceleration for some specific setups. This error could mean a serious issue in the motor-controller installation.

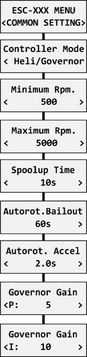

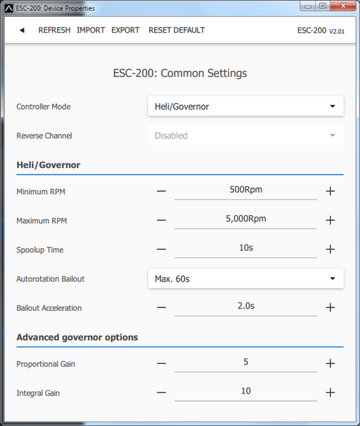

Heli/governor mode

The speed controllers contain a fast and precise governor function. You can configure the governor mode in many aspects according to your preferences.

Before enabling the governor mode, please make sure the blades are removed. In the Common Setting menu, set the Controller Mode to "Heli/Governor" and proceed through the settings below:

- Set the minimum and maximum RPM of the main rotor according to your preferences. As soon as you move the throttle away from the idle position, the controller slowly spools up until it reaches the target speed. The speed is calculated according to the throttle channel value, where low throttle corresponds to the "Minimum RPM" and high throttle corresponds to "Maximum RPM".

- Set the Spool-up Time to make the motor startups as smooth as possible. You may set the time up to 60s. The spool-up time is applied when the motor starts from zero

revolutions or if the autorotation bailout is disabled.

- Configure the Autorotation bailout time and autorotation acceleration time. The autorotation bailout function is used in case you need to quickly exit the autorotation and prevent your model from crashing. In this case, as soon as you move the throttle channel away from the idle position, the "Autorotation acceleration" will be used to spin the motor until it reaches the required speed. The "Autorotation bailout" parameter sets the time after switching off the motor, when the autorotation bailout function may be activated. After exceeding this time, a standard spool-up time will be applied.

- Advanced settings: Governor gains – (P)roportional and (I)ntegral. You may modify the gains to fine-tune the controller response to fast changes in the load during flight manoeuvres. Please perform the changes only in small steps and verify the resulting behaviour in a short test flight.

- Increase the P gain to eliminate small RPM fluctuations during straight flight, e.g. while hovering. If you hear some unexpected noise in the motor/gearbox (which means fast oscillations), reduce the P gain by 20 %.

- Increase the I gain to hold the precise revolutions during manoeuvres. If the motor speed starts oscillating noticeably, reduce the I gain by 20%.

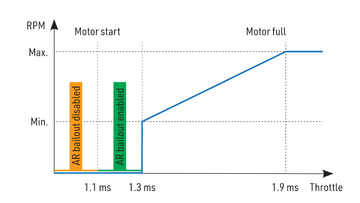

- In the Governor mode, manual throttle endpoints are always used (by default 1.1–1.9 ms) and Active braking is enabled as well.

The picture below shows RPM response vs. throttle position. In this case, default throttle endpoints have been used (1.1–1.9ms).

Motor direction reversing

The motor reverse feature is available for RC systems with bidirectional bus support (EX Bus, P²Bus, SRXL2, S.Bus2). To control the motor direction you need to define an additional channel transferred through the bus system. Both cables (red and black) of the KAVAN Smart PRO speed controller must be properly linked to the receiver. First, you need to create an additional channel on your transmitter to control the motor direction. This channel should be operated by a two-position switch.

Futaba/Spektrum:

Use one of the AUX channels and remember the channel number. It is not necessary to use just the channels available on your receiver since the RC systems usually offer more channels over the bus than the physical number of receiver ports.

Example: If you use Spektrum NX6 and a 6-channel receiver, you may still use channel No. 7 (AUX2) to control the reversing feature over the bus.

JETI:

Create a new model function in the Model - Functions Assignment menu and assign a spare two-position switch. After that, in the Model – Servo Assignment menu, assign the function to one of the receiver channels (1–16). Again, you may use the channels that are not directly available on the receiver outputs (e.g. 13–16) since they will be transferred through EX Bus without limitation.

PowerBox:

Create a new model function in the Function menu by pressing the "+" button and assign it a 2-position control switch. Choose one of the available servo output channels (1–16). The switch position will be transferred over the P²Bus to the speed controller.

To enable the motor reverse function in the controller, set the "Controller Mode" to "Normal/Reverse" and set the correct channel from the previous step. You may also play with the brake settings and reverse wait time under the "Manual" brake type.

Check the function: As soon as you flip the direction switch, the controller activates braking, and after some short pause, the motor starts spinning in the opposite direction.

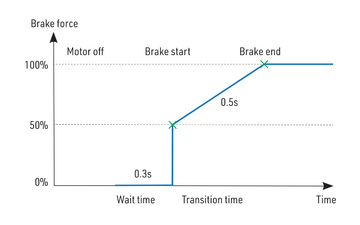

Telemetry and settings

Plug the red data cable into the sensor slot of the JETIBOX / SMART-BOX (or corresponding receiver). Power it up with a battery (4.5–8.4 V). Now you can safely configure the controller using the arrows on the terminal. If you use an external (optional) switch connected to the ESC, please make sure that the controller is turned on.

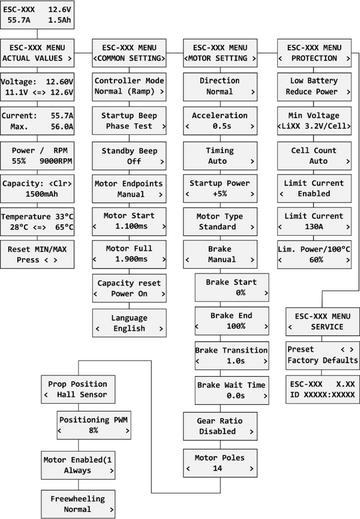

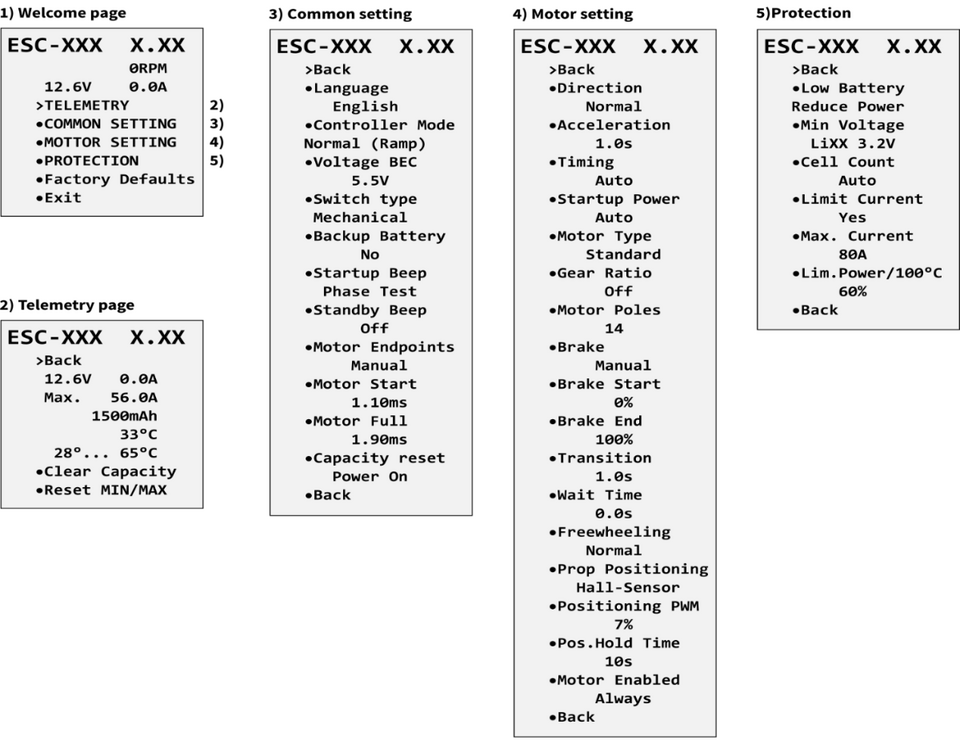

KAVAN Smart PRO controllers are compatible with JETIBOX programming. The JETIBOX menu is divided into five sections:

Actual values

- displays the latest telemetry values together with minimums and maximums.

- Available telemetry: Voltage, current, capacity, RPM, power (per cent), temperature.

- If the motor chip ID is connected, also motor identification and temperature are shown.

- Reset Min/Max - press the left and right buttons together to reset all minimums and maximums.

Common settings

- basic controller settings

- Controller mode - basic controller mode (normal or fast).

- Startup beep - choose a melody played after the controller initialization.

- Standby beep - you can activate short repeated beeps as an indication of a powered motor drive.

- Motor endpoints, motor start, motor full - settings related to throttle input signal decoding.

- Capacity reset - you can choose at which moment the capacity and consumed energy are reset:

- Power on - the capacity is reset after the controller initialization. However, the capacity from the previous run will be displayed initially until you start the engine.

- Voltage change - the capacity is cleared after you connect a battery with a similar (or greater) voltage compared to the maximum battery voltage from the previous run. This means that each time you connect a fully charged battery of the same chemistry and number of cells, the capacity will be cleared.

- Manual - the capacity/energy is never cleared and you must perform the reset manually.

- Language - you can choose the language of the JETIBOX screen.

Motor settings

- settings related to motor parameters.

- Direction, acceleration, timing, startup power, motor type, gear ratio, motor poles - see the Motor Settings chapter.

- Brake related settings - see the Brake Configuration chapter.

- Prop position, positioning PWM, position hold time - see the chapter Propeller positioning.

- Motor Enabled (0/1) - motor operation can be enabled or disabled based on the logical state of the specific input “IN B.2” (connector pinout from left to right: 1 = Hall sensor input, 2 = Motor enable input, 3 = 3.3V, 4 = Ground). If you choose an “InputPin Log0/1” option, you must pull the throttle low before starting the motor. On the other hand, after choosing the "Autostart Log0/1" option, the controller will start spinning as soon as the input pin state allows it and the throttle position is above the idle position.

- Freewheeling - enables freewheeling/active braking motor operation.

Protection

- ESC and battery protection settings.

- Low battery - behavior when the battery is discharged. Either set to slowly reduce the motor power, or shut down the motor immediately. The minimum safe voltage is based on number of cells (cell count) and voltage per cell.

- Limit current - enable this feature to prevent high current peaks and system overload.

- Limit power at 100°C - you can edit the maximum allowed PWM after the controller temperature exceeds 100 °C. The model must be operable, but the temperature must not increase anymore.

Service

- In this menu, you can view the device version and reset it to the default factory configuration.

Available EX and P²Bus telemetry:

- Battery voltage (V)

- Motor current (A)

- Capacity (mAh)

- Speed (RPM)

- PWM (%)

- Power (W)

- Motor run time (s)

- Energy (Wmin) - a useful feature for competitions where the total energy is limited (F5B, F5D).

- Temperature (°C)

- External temperature (°C) - if the motor identification chip is connected, the ESC forwards motor temperature in its own telemetry.

- Motor status:

- 0 = initial state

- 1 = motor running

- 2 = braking

- 3 = positioning started

- 4 = position found.

- 5 = position error (prop out).

- BEC voltage (V)

- BEC current (A) - KAVAN Smart PRO 145 only.

The KAVAN SMART PRO controller is recognised by default as an "Air-ESC" sensor.

Futaba and Multiplex connection

Futaba and Multiplex systems do not offer wireless device configuration. The telemetry transmission is possible with the following fixed sensor slots:

| Futaba S.Bus2 slot | Note | Slot Multiplex MSB | |

|---|---|---|---|

| Speed | 2 | Select the RPM sensor on slot 2. | 6 |

| Current | 3 | Select the SBS01C current sensor on slot 3. | 3 |

| Voltage | 4 | 2 | |

| Capacity | 5 | 4 | |

| Temperature | 6 | Select the Temp125 sensor on slot 6. | 5 |

| PWM (0–100%) | 7 | Select the Temp125 sensor on slot 7. | - |

| Note | Manual detection in menu Linkage - Sensor. | Automatically detected by the transmitter. | |

PowerBox Telemetry

From version 1.09, the KAVAN Smart PRO controller can recognise the PowerBox P²Bus telemetry protocol. Connect the Telemetry cable (red connector) to the P²Bus port of the receiver. The transmitter scans for attached sensors as soon as the receiver is powered up and the controller telemetry should be available within 2.5 seconds. After that, you are free to assign the telemetry to any desktop widgets and alarms. Available telemetry is similar to the Duplex EX telemetry (see above). The controller configuration through the PowerBox transmitter is not available at the moment.

Spektrum Integration

From version 1.06, the Spektrum telemetry support has been integrated into a special firmware version. This alternative firmware offers the SRXL2 telemetry and setting using the TextGen protocol. The KAVAN Smart PRO controller is represented in the transmitter by two telemetry devices:

- "ESC" shows battery voltage, current, BEC voltage, ESC temperature, RPM and power output.

- "Flight Pack Capacity" sensor that shows the consumed battery capacity.

Connect the Throttle cable (black connector) to the Thr (1) receiver port. For proper telemetry/setting, also connect the Telemetry cable (red connector) to the Prog/SRXL2 receiver port. The controller normally delivers only numerical telemetry. The textual menu (TextGen) is available only after a special procedure is performed during startup:

- We assume the Throttle and Telemetry cables are connected correctly and the transmitter is turned on. Now push the throttle high.

- Turn on the ESC either by connecting the flight pack or by flipping the external switch.

- The motor will beep indicating detection of the high throttle impulse. After 3 seconds, another beep announces entering the programming menu.

- Now you may pull the throttle low. On the transmitter's main screen scroll right to locate the TextGen menu. The motor will never start spinning if the textual menu is enabled. To enable normal motor operation, you have to leave the TextGen menu by choosing the "Exit" option on the first page.

- Navigation in the menu is provided by the transmitter's sticks – the elevator stick moves the cursor up/down and the aileron stick changes the selected value.

- The configuration changes are saved immediately after any value is edited.

The KAVAN Smart PRO version 2.01 and later is compatible with Spektrum single-cable operation (Smart Throttle). To enable this function, just plug the red telemetry cable into receiver channel No.1 and keep the other (black) cable unplugged. You will be able to control throttle as well as receive telemetry. This approach is compatible with the AR10400T receiver family as well.

Safety information

- Operate the KAVAN SMART PRO controller always in a dry environment and within the device limits stated in this guide. Never expose the device to excessive heat or cold outside the working area.

- Provide sufficient airflow to prevent controller overheating.

- Never exceed the maximum allowed operating voltage of the controller/motor.

- Do not increase the cable length between the controller and the motor. If you need to extend the wires between the controller and the battery to more than 30 cm (in total), solder multiple high-capacity Low-ESR capacitors (220–470 µF) in parallel to the power wires as close to the controller as possible. For each centimetre beyond the specified cable length, add a capacitance of 1µF for every Ampere of current passing through. For example, if you exceed the limit by 10 cm with a current of 100 A, solder a 1000 µF capacitor pack.

- Always use high-quality connectors in good condition. Replace them if any visible sign of wearing appears.

- Always remove the propeller before making any changes in the drive setup.

- Never disconnect the ESC from the battery while the motor is spinning.

- Do not remove the cover and heat sink from the device, and do not try to implement any changes or modifications. This can lead to total destruction and to the denial of any warranty claims.

- Always check the polarity of the connection. Never inverse the polarity – this could lead to total destruction.

Firmware update

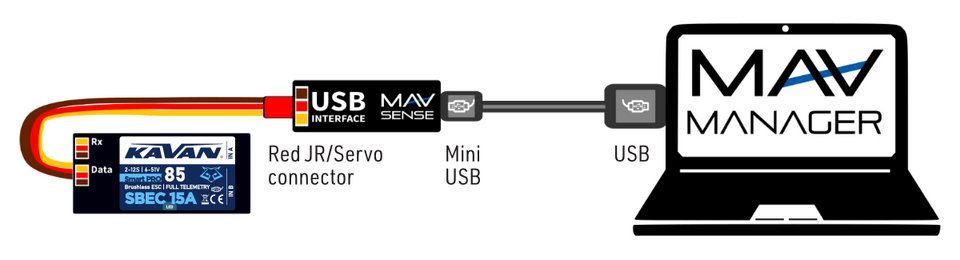

Firmware updates for KAVAN Smart PRO controllers are transferred from a PC via the USB interface. The required programs and files are available at www.mavsense.com.

Install the MAV Manager software and the USB drivers on your computer. Check the system requirements.

- Make sure that the flight pack is disconnected and the KAVAN Smart PRO ESC is unpowered.

- Connect the USB interface to your PC, run MAV Manager - Updater and select the correct COM Port.

- Connect the KAVAN Smart PRO ESC according to the picture below – use the red (telemetry) port. The controller will be automatically detected.

- Select the correct *.BIN file and press the Update button.

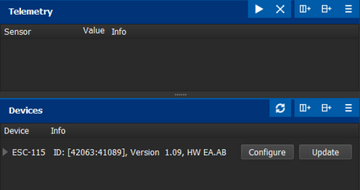

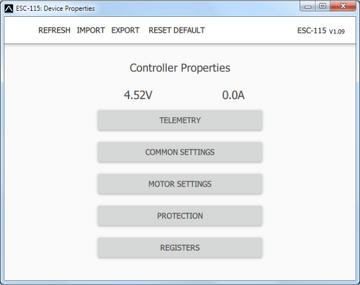

PC configuration

It is possible to use the MAV Manager software (1.4.0 and later) to conveniently configure all controller settings, display real-time telemetry and make a backup of the configuration. The configuration menu contains four buttons in the top toolbar:

- Refresh - forces the configuration to be reloaded from the controller.

- Import - imports the settings from a file. If you have several speed controllers and want identical settings for all of them, simply import the same settings to each controller.

- Export - exports the settings from the controller to a file. You can easily create a backup configuration stored on your PC. After creating a backup, you may easily experiment with the controller settings and later revert back to the original configuration by pressing the "Import" button and choosing the original exported file.

- Reset default - resets the controller to factory defaults and reloads all the settings.

Connect the controller to a computer using the USB interface. It is automatically detected by the MAV Manager.

The controller properties are available by pressing the "Configure" button.

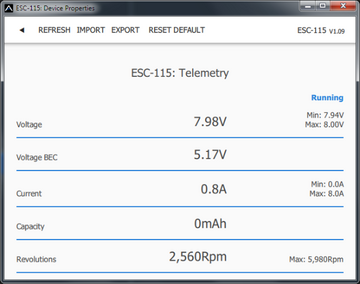

Real-time telemetry with min/max values. MAV Manager is also capable of creating a log file from real-time telemetry data that can be viewed, analyzed, imported and exported.

Motor Settings. Whenever a configuration change is made, the new value is immediately transferred to the controller and stored in memory. No additional confirmation is required. For safety reasons, some parameters are only applied after the motor has stopped.

Manufacturer

All KAVAN Smart PRO electronic speed controllers are made in Czechia by MAV Sense s.r.o.

E-mail: info@mavsense.com | Web: www.mavsense.com

Recycling and waste disposal note (European Union)

Electrical equipment marked with the crossed-out waste bin symbol must not be discarded in the domestic waste; it should be disposed of via the appropriate specialised disposal system. In the countries of the EU (European Union) electrical devices must not be discarded via the normal domestic waste system (WEEE - Waste of Electrical and Electronic Equipment, Directive 2012/19/EU). You can take your unwanted equipment to your nearest public collection point or recycling centre, where it will be disposed of in the proper manner at no charge to you. By disposing of your old equipment in a responsible manner you make an important contribution to the safeguarding of the environment.

EU declaration of conformity (European Union)

Hereby, KAVAN Europe s.r.o. declares that these KAVAN Smart PRO line brushless electronic speed controllers are in compliance with the essential requirements as laid down in the EU directive(s) concerning electromagnetic compatibility. The full text of the EU Declaration of Conformity is available at www.kavanrc.com/doc.

Guarantee

The KAVAN Europe s.r.o. products are covered by a guarantee that fulfils the currently valid legal requirements in your country. If you wish to make a claim under guarantee, please contact the retailer from whom you first purchased the equipment. The guarantee does not cover faults which were caused in the following ways: crashes, improper use, incorrect connection, reversed polarity, maintenance work carried out late, incorrectly or not at all, or by unauthorised personnel, use of other than genuine KAVAN Europe s.r.o. accessories, modifications or repairs which were not carried out by KAVAN Europe s.r.o. or an authorised KAVAN Europe s.r.o., accidental or deliberate damage, defects caused by normal wear and tear, operation outside the Specification, or in conjunction with equipment made by other manufacturers. Please be sure to read the appropriate information sheets in the product documentation.