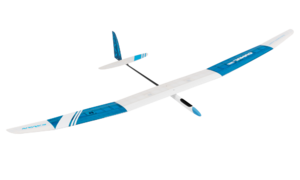

KAVAN Cumul 100 glider kit 2540mm - Instruction manual

Introduction

Those old glider pilots of yore used to say that really good models start with a 100“ wingspan… With our Cumul 100, you will easily find they were completely right. A high-performance thermal glider is a gem for any Sunday flyer - there is nothing like relaxed sailing on a nice summer day, circling in the thermal under white clouds; or silent soaring in the evening calm when you can sit down and relax watching your model flying almost all alone… Of course, Cumul 100 can do much more than that - thanks to its “full house” wing with ailerons and flaps you can unleash your computer radio skills: programming several flight conditions for improved penetration when seeking the thermal, or increasing the lift when you are in the thermal, or the incredibly effective butterfly brake for spot-on landings… to name just a few possibilities Cumul 100 offers. And, if you are a contest-minded pilot, Cumul 100 conforms to the rules of the international FAI F5J category as well as many of those “all-up-last-down” or “endurance” national categories.

KAV02.8019 KAVAN Cumul 100

Precautions

This RC model is not a toy. Use it with care and strictly following the instructions in this manual.

Assemble this model following strictly these instructions. DO NOT modify or alter the model. Failure to do so, the warranty will lapse automatically. Follow the instructions to obtain a safe and solid model at the end of the assembly.

Children under the age of 14 must operate the model under the supervision of an adult.

Make sure the model is in perfect condition before every flight, check that all the equipment works correctly and that the model is undamaged in its structure.

Fly only on days with a light breeze and in a safe place away from any obstacles.

You must build the model according to the instructions. Do not alter or modify the model, as doing so may result in an unsafe or unflyable model. Take time to build straight, true and strong. Use proper radio and other equipment that is in first-class condition, properly install all the components and test their correct operation before the first and any further flight. Fly the model only with competent help from a well-experienced modeller if you are not already an experienced RC pilot.

Specification

| Wingspan | 2540 mm |

| Length | 1435 mm |

| All-up weight | 750 g |

| Wing section | AG 40–42 |

| CG position | 77–81 mm |

| Controls | Aileron, flap, rudder, elevator, (motor) |

Recommended RC equipment

- Aileron and flap servo: KAVAN GO-1023MG 4×

- Rudder and elevator servo: KAVAN GO-1020MG/GO-1021MG 2×

- Receiver battery: 2S LiPo 800–1000 mAh 7.4 V

Recommender RC equipment (electric)

- Aileron and flap servo: KAVAN GO-1023MG 4×

- Rudder and elevator servo: KAVAN GO-1020MG/GO-1021MG 2×

- Motor: KAVAN C2836-1120, KAVAN PRO 2836-1050 w. 10×6" folding propeller (32mm spinner)

- ESC: KAVAN R-40SB, KAVAN PRO-30SB, KAVAN PRO-40SB

- Flight battery: 3S LiPo 750–850 mAh 11.1 V

Recommended glues

Unless stated otherwise, use medium cyanoacrylate (CA) glue (KAV56.9952 Power CA Medium). D-box sheeting and wing ribs are better glued using a water-resistant white aliphatic resin, like our KAV56.9960/KAV56.9961 White Glue SUPER (alternatively, you can use this sort of glue for most of the wood-to-wood joints). The highly loaded parts (wing roots, wing main spars, firewall etc.) should be glued together using 30-minute (or slower) epoxy offering high strength and enough time for the correct positioning.

Tools and accessories

- Very sharp modeller‘s knife (KAV66.770 with no. 11 blades)

- Scissors

- Electric drill with drill bits

- Wire cutter

- Long nose pliers

- Screwdrivers

- Razor saw

- Sandpaper No. 80, 100, 180, 360–400

- Needle files

- Soldering iron and solder

- Clothing pegs

- Modeller’s pins (KAV66.0355)

- Epoxy mixing stick and vessel

- Masking tape, clear sticky tape

- Rubbing alcohol (for cleaning up excessive epoxy)

- Paper tissue or soft cloth (for cleaning up excessive epoxy)

- Straightedge with scale

- Square edge

- Thin clear plastic film (for protecting the building plan)

- Permanent marker

- Modeller’s sealing iron, heat gun (for covering)

- Lightweight balsa filler

Model assembly

The empennage

Everything has been designed extremely light, yet strong enough. The horizontal tailplane is removable for easy transport/storage.

- Trial fit the parts of the horizontal stabiliser, elevator, fin and rudder – no glue yet! Sand as necessary to obtain the perfect fit. Bevel the leading edge of the rudder and elevator to allow the control surface travel as indicated on the building plan.

- Epoxy the T8 and T9 plywood inserts into the T10 stabiliser centre part. Glue together all the parts using medium cyano or white glue. (Fig. 1+2)

- Put the tail feathers aside for now. They will be finished after covering, once the tailplane seat is installed to the tail boom.

Wing

Wing centre section

- Cut out all the CNC-milled ribs using a sharp modeller’s knife or jigsaw, check them with the plan and mark the numbers on them with a soft pencil or marker. Sand as necessary to fit all spars easily.

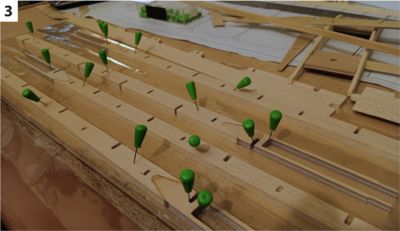

- Assemble the main spar shear webbing. Epoxy the W30 wing joiner bays to the W29 balsa parts. Enclose the bays; epoxy the W31 plywood plates (front side of the shear webbing) and W32 (rear side). Prevent the epoxy from hardening inside the bays. Put the parts together with the carbon joiner inserted, then immediately remove the joiner (do not forget to clean the joiner using paper tissue and rubbing alcohol before the glue sets). (Det. B, Fig. 3)

- Bind the joiner bays with the provided Kevlar® thread and soak with medium CA or epoxy. Epoxy together both two shear webbing halves reinforcing the joint with the plywood joiners W27 (short one, front side) and W28 (long one, rear side). (Det. B, Fig. 3+4+5)

- Epoxy together the wing central ribs W1 and W2. Insert 3 mm beech dowels into the holes to obtain the correct match.Note: Make a left and right pair of ribs.

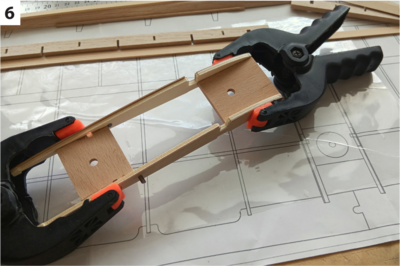

- Epoxy the plywood wing bolt plates W15 and W18 between the W1/W2 ribs. Glue the balsa blocks W16 and W17 onto them (trim the W17 first to match the outline of the W1 ribs). Sand the W16 flush with the edge of W2 ribs. (Fig. 6)

- Glue the W26 flap servo trays between the W5 ribs.Note: Make a left and right pair of assemblies.

- You can use medium cyano for glueing most of the wing centre section parts. In that case, you are supposed to put together most of the wing without glue at first. Once checked for the correct alignment, the cyano is applied to the joints from the outside. Or you can use white glue. In that case, the wing is assembled step by step, pinned down on the building plan protected by a thin clear plastic film. Start with pinning down the W9 bottom main spar. The W11, W12, W14 and W38 parts are to be glued after the wing is removed from the building board.

- Assembling the wing using cyano: Insert all ribs and riblets into the respective notches, slide on the W13/W19 trailing edge. Cyano the W6 ribs to the shear webbing using the 7 deg dihedral jig (the W7 outer ribs are to be glued later - after the wing centre section has been paired with the wing panels).

- Insert, but not glue, the W11 auxiliary spar (5 mm balsa) and the W12 flap leading edge (7 mm balsa). Align the top edge of these parts flush with the top edge of the ribs (you will trim the protruding part at the bottom later, once glued in place).

- Cyano the W25 flap horn blocks in place.

- Double-check the correct position of all ribs and spars. Lay the wing on the building plan. Once satisfied, apply cyano to all joints.Note: Be sure not to glue the W11 and W12 parts to each other, just to the ribs.

- Insert and cyano the W10 rear spar (6×3 mm pine stick).

- Pin down the wing centre section to your building board. Butt joint the W9 main spar (10×2 mm pine) to the edge of the W39 top D-box sheeting (1.5 mm balsa). Apply white glue to the top of the ribs, riblets and the main spar shear webbing. Insert the W9 main spar into the notches in all ribs and pin it down. Then step by step pin down the W39 balsa sheeting to the ribs.

- Once the glue has cured, remove the wing from your building board. Glue the W14 support spar in place as well as the W9 bottom main spar. Use white glue to secure the W38 bottom D-box sheeting in place. (Fig. 7)

- Sand the front edge of the W39 and W38 balsa sheeting flush with the front edge of the ribs and glue the W8 leading edge in place.

- Glue the W24 bottom cover plates of the flap servo bays between the W5 ribs. Glue the W33 flap root ribs in place.

- Sheet the space between W2 ribs from the bottom and top with W20a, W20b (with the W40 connector reinforcement plate glued on top), W21, W22 and W23. (Det. C)

- Sand the sheeting flush with the edges of W2 ribs. Drill the hole for the front wing bolt through the W39 top sheeting. Taper the top edges of the wing bolt holes to match the supplied countersunk screws. Soak the tapered area with thin cyano to reinforce it.

- Glue the W47 gussets in place.

- Fine sand the entire wing centre section, pay attention to the leading edge and sand the W6 ribs flush. Trial fit the flap servos. Prepare the aileron and flap extension cables. To allow threading the cables after the wing has been covered, you should put a thread through the holes in ribs secured by strips of sticky tape. Or you can glue 6 mm plastic tubes (not included in the kit). See the dotted lines on the building plan. There is a pair of the MPX8 8-pin connectors supplied in the kit suitable for the cable connection of the aileron and flap servos and your receiver. The male part (with pins) is to be secured by screws into the fuselage and the female part into the wing. (Fig. 11+21)

- Solder the extension cables with (+) and (-) pins shared, the remaining pins are for the servo signal leads. You can use regular servo connectors between the wing centre section and outer panels, but the sturdier MR30 connectors (KAV36.131 - not supplied in the kit) are more suitable for the task. If you are going to use them, install the male part (with pins) of the connector into the wing centre section. It is probably best to install all the cables before the wing is covered. Do not forget to double-check the correct polarity and connection first! The connectors are to be cyano-ed to the wing after the covering.

- Use a fine razor saw to cut the root part of flaps through the W13/W19 trailing edges and between W33 and W2 ribs. Cut through the ribs between the W11 auxiliary spar and W12 flap leading edge with a sharp modeller’s knife or razor saw and remove the flaps. Bevel the leading edge at a 27-degree angle, allowing the up deflection of the flaps (flaps are hinged on the bottom side of the wing). (Fig. 8)

- Trial fit the carbon wing joiners into the respective bays. There should be a tight fit, no play. If there was a significant play, put some epoxy in the appropriate area of the joiner and sand as necessary once the glue hardens. Trial fit the W7 liteply outer ribs - do not glue yet.

Wing outer panels

- The wing outer panels are to be assembled in one piece. The winglets will be cut off subsequently. Build the wing panel on a flat building board. The trailing edge has to be supported so the wing tip is 2 mm above the building board creating the required washout (the railing edge lays flat on the working surface at the W50 root rib, then it is supported in at least three points so it is 2 mm above the building board at the W74 end rib).

- Assemble the main spar shear webbing. Epoxy the W37 wing joiner bays to the W34 balsa parts. Enclose the bays. Epoxy the W36 plywood plates (front side of the shear webbing) and W35 (rear side). Bind the joiner bays with the provided Kevlar® thread and soak with medium CA or epoxy.Note: Make a left and right pair.(Det. A, Fig. 3+9+5)

- Assemble the wing panels without glue at first. Insert all ribs and riblets into the respective notches in the shear webbing. There are two 5 mm ribs W66 and W67 dividing the outer panel and the winglet (you can glue both two ribs square to the shear webbing and bevel both at 4 degrees angle once the winglet has been cut off, or you can one of them - preferably W67) glue in 8 degrees angle using the supplied 8 deg dihedral jig).

- Slide on the W83/W84 trailing edges onto the ribs. Cyano the W50 root ribs to the shear webbing using the 7 deg dihedral jig (the W49 outer ribs are to be glued later - after the wing panels have been paired with the wing centre section).

- Insert, but not glue, the W79 auxiliary spar (5 mm balsa) and the W80 aileron leading edge (7 mm balsa).

- Cyano the W46 aileron horn blocks between the W56 and W58 ribs (not to the W80 yet).

- Double-check the correct position of all ribs and spars; lay the wing on the building plan. Once satisfied, pin down the wing outer panel to your building board with the trailing edge supported as described above. Apply medium cyano to all joints (do not glue the W79 and W80 parts yet). Insert and cyano the W78 wing panel rear spar (6×3 mm pine stick) and the W85 winglet rear spar (4×2 mm pine).

- Butt joint the W77 main spar (10×2 mm pine) to the edge of the W89 top D-box sheeting (1.5 mm balsa). Apply white glue to the top of the ribs, riblets and the main spar shear webbing. Insert the W89 main spar into the notches in all ribs and pin it down. Then step-by-step pin down the W89 balsa sheeting to the ribs.

- Butt joint the W91 winglet main spar (8×2 mm balsa) to the edge of the W88 top D-box sheeting (1.5 mm balsa). Apply white glue to the top of the ribs, riblets and the main spar shear webbing. Insert the W91 main spar into the notches in all ribs and pin it down. Then step-by-step pin down the W88 balsa sheeting to the ribs.

- Once the glue has cured, remove the outer wing panel from your building board. Align the top edge of the W79 and W80 flush with the top edge of the ribs and glue them to the ribs, not to each other. Trim the protruding part at the bottom side of the wing. Put the wing panel down onto your building board to check the trailing edge is straight and elevated by 2 mm at the wing tip.

- Glue the W43 wing tip in place.

- Glue the W90 support spar in place as well as the W77 and W91 bottom main spar. Use white glue to secure the W87 and W86 bottom D-box sheeting in place.

- Sand the front edge of the W87/W89 and W86/W88 balsa sheeting flush with the front edge of the ribs and glue the W75 and W76 leading edges in place.

- Glue the W48 winglet gussets in place. Glue the W44 bottom cover plates of the aileron servo bays between the W56 and W58 ribs.

- Sand the W50 root ribs flush. Trial fit the carbon wing joiners into the respective bays. There should be a tight fit, no play. Trial fit the W49 liteply outer ribs - do not glue yet.

- Slide the wing panel onto the carbon wing joiner together with the W49 and W7 liteply ribs. Slide on the wing centre section as well. Check how the ribs and wing parts match. Trim them as necessary to achieve a perfect fit. Once satisfied, epoxy the W7 and W49 ribs in place.

- Fine sand the entire wing panels, pay attention to the leading edge.

- Cut off the winglets. Use a fine razor saw to cut through (from the bottom) between the W66 and W67 ribs. If you have glued the ribs square to the main spar, now bevel both at a 4-degree angle to achieve the required 8 degrees winglet dihedral.

- Cut through the ribs between the W79 auxiliary spar and W80 aileron leading edge with a sharp modeller’s knife or razor saw and remove the flaps. Bevel the leading edge at a 28-degree angle allowing the down deflection of the ailerons (ailerons are hinged on the top side of the wing).

- Glue the winglets to the wing panel (the butt joint protects the wing as there is a good chance the winglet breaks off in an accident - whilst the rest of the wing will remain undamaged).

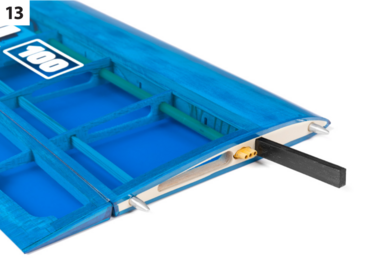

- Glue the W103 aluminium alignment pins into holes in W49/W50 ribs. (Fig. 13)

- Trial fit the aileron servos. Prepare their extension cables. To allow threading the cables after the wing has been covered you should put a thread through the holes in ribs secured by strips of sticky tape. Or you can glue 6 mm plastic tubes (not included in the kit) - see the dotted lines on the building plan. You can use regular servo connectors between the wing centre section and outer panels, but the sturdier MR30 connectors (KAV36.131 - not supplied in the kit) are more suitable for the task. If you are going to use them, install the female part (with sockets) of the connector into the wing panels. It is probably best to install all the cables before the wing is covered. Do not forget to double-check the correct polarity and connection first! The connectors are to be CA-glued to the wing after the covering.

Covering

- Thoroughly sand the surface of all parts with No. 360–400 sandpaper and carefully vacuum all the dust (the iron-on film does not stick well to a dusty surface; the dust also contains hard grains released off the sandpaper capable of ruining the smooth coating of your sealing iron quickly).

- Use as light iron-on film as you can get (transparent KAVAN film, Oracover®, Oralight® etc. – not supplied in the kit). Follow the instruction manual supplied with the covering film of your choice please.

Hinging the control surfaces

- Use strips of high-quality hinging tape (available in hobby shops) or strips of the same iron-on film you used for the covering. Remember to apply the tape with the control surface deflected to the limit to get free movement of the particular control surface.

Aileron and flap servo installation

- If not done before covering, insert the aileron and flap servo extension cables in place. Install the aileron and flap servos with the arm set to neutral with your radio on (to allow for the max. travel it is recommended to set the aileron servo arms offset by 15–20 degrees forward and flap servo arms by 15–20 degrees back). Cyano the W100 flap horns (longer fibreglass arms without triangular opening) into the W25 blocks and the W101 aileron horns (shorter fibreglass arms without triangular opening) into W46 blocks. Make the servo linkage: cyano one all-plastic quick link and one quick link with metal pin to the ends of Ø2 mm carbon rods (the all-plastic quick link is a sort of safety device protecting the servos on a rough landing or other mishaps). (Fig. 10)

- Double-check the correct operation of the aileron and flap servos. Once satisfied, cyano the MPX8 and MR30 (if used) connectors in place. (Fig. 11+12 +13)

- Secure the W41 and W42 servo covers with strips of thin double-sided sticky tape.

Fuselage

- The fuselage consists of the F2 carbon reinforced fibreglass part and the F1 carbon tail boom with milled slots for the fin and horizontal tailplane pylon.

- Horizontal tailplane pylon: Epoxy the aluminium captive nuts M4 and M3 into the F9 liteply horizontal stabiliser pylon matching the openings in the F10 horizontal tailplane seat that is to be epoxied square onto the top of the pylon. Glue the F11 balsa blocks on the sides of the F9 pylon. Sand the blocks to match the outline of F9 and F10. Trial fit the pylon into the slot in the F1 tail boom. Trim the bottom of the F11 blocks until the F9 connects with the bottom of the tail boom and the balsa blocks match the surface of the boom. Round the leading and trailing edges of the pylon and cover it with your favourite iron-on film - now it is prepared for the final assembly. (Fig. 14)

- Drill and cut 2 mm slots for the rudder (right side) and elevator (left side) push rod exits - refer to Fig. 16+17. Insert the elevator and rudder push rod sleeves into the F1 tail boom threading them out through the respective exit slots. Epoxy the horizontal tailplane pylon in place. (Fig. 15 + 16 + 17)

- Slide the smallest of the three push rod plywood holders (packed in bag. no. 1) onto the push rod sleeves and push inside the tail boom using a suitable hardwood stick. Secure it with a small amount of epoxy or cyano.

- Attach the horizontal tailplane to the pylon and secure it with screws; remove the covering film from the fin-tail boom contact area and insert the fin into the slot in the tail boom. Trim as necessary; double-check check the fin was square to the horizontal tailplane. Once satisfied, epoxy the fin in place. Epoxy the F6 tail skid in place as well.

- Insert and glue the two remaining plywood push rod holders into the tail boom.

- Tow hook (glider): Disassemble the supplied tow hook, use the F8 plate as a template to drill the openings for the M3 screws and 4.5–5 mm slot for the F7 hook and its setting screw (assuming the CG position is 77–81 mm behind the leading edge of the wing, the tow hook is to be positioned 4–10 mm in front the CG depending on the wind). Install the tow hook into the fuselage. (Fig. 18)

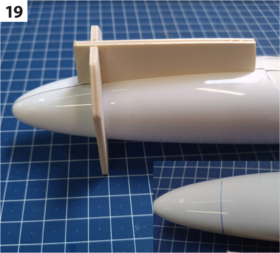

- Firewall (electric): Glue together the liteply nose cutting jig (32 mm spinner is assumed). Mark the cutting line with a soft pencil; cut the nose with a razor saw and sand flush. Epoxy the F3 firewall in place (check whether your motor matches the firewall first. Trim if necessary or make a new firewall of 3 mm plywood or fibreglass plate). (Fig. 19)

- Trim the servo tray F4E to match your servos if necessary and insert it into the fuselage (the long cut-out for your flight pack towards the tail). The tray is to be glued in place only after you have checked the correct CG position with your motor, ESC, servos and flight pack (3S LiPo 750–850 mAh for the contest flying. Anything 3S that will fit the fuselage for Sunday flying) installed. (Fig. 20)

- Aileron and flap servos connector: A pair of the MPX8 8-pin connectors is supplied in the kit suitable for the cable connection of the aileron and flap servos and your receiver. The male part (with pins) is to be secured by screws into the fuselage, and the female part into the wing. Solder the extension cables with (+) and (-) pins shared, the remaining pins are for the servo signal leads. (Fig. 21)

- Servo tray (glider): The servo tray F4 supplied in the kit is tailored to KAVAN GO-1020MG/GO-1021MG servos or similar. The servos are to be secured using the supplied fibreglass stoppers. If you are going to use different servos, trim the tray as necessary or make a new one to match your servos. Insert the servo tray into the fuselage allowing the clearance for your receiver battery in the nose. Once satisfied, epoxy the tray in place. (Fig. 22)

- Tail boom installation: Insert the tail boom into the fibreglass fuselage carefully - trim the bay in the fuselage if necessary. Check whether the elevator and rudder pushrods are still moving freely in their sleeves.

- Once satisfied, attach the horizontal tailplane and wing centre section. Apply 30 min epoxy to the contact surfaces and insert the tail boom into the fuselage taking care of the horizontal tailplane and the wing were parallel. Double-check the correct alignment before the glue cures.

- Elevator and rudder servos and horns installation: (If you are building the electric version, install your motor with propeller and ESC, secure the wing with servos installed and the horizontal tailplane, insert your receiver, flight pack and the F4E servo tray with servos into the fuselage. Moving the servo tray and flight pack try to achieve the CG position 77–81 mm behind the wing leading edge without any additional ballast if possible. Once satisfied, epoxy the F4E servo tray in place.) Cut the push rot sleeves to make room for the full servo travels (leave a margin for the ball links and threaded couplers). Remove the piano wire push rods and solder the M2/0,8 mm brass threaded couplers to one end. Screw the M2 ball links on. Insert the push rods back into their respective sleeves and secure the ball links to the rudder and elevator horns (those with triangular openings) with supplied screws. (Fig. 16+17)

- Fit the horizontal tailplane to the fuselage. Insert the control horns into the rudder and elevator - do not glue them yet. Set the servos in a neutral position with your radio on and mark the correct length of the push rod wires. Make a “Z” bend on the end of the pushrods or solder the M2/0,8 mm brass threaded couplers, screw on the plastic quick-links and attach the push rods to the rudder and elevator servo arms. Check once again and only then CA-glue the control horns in place. Do not forget to glue the end of the elevator push rod tube to the fuselage in the cockpit.

- Canopy: You can secure the canopy simply using strips of clear sticky tape or you can make a spring lock as per Fig. 23. Make two ca 65 mm long loops of 1.0–1.2 mm piano wire (not supplied in the kit) and epoxy them inside the canopy overlapping by 8–10 mm. Bend the ends up slightly. (Fig. 23)

Tow hook (glider)

- Keep the recommender CG position 77–81 mm behind the wing leading edge. Set the tow hook 4 mm in front of the CG for the first flight. (You have to loosen the front screw to move the tow hook.)

Power system installation (electric version)

- Fit your motor using the appropriate screws to the firewall. Secure the ESC and power pack using hook-and-loop tape into the cockpit. With your RC set on test whether the motor rotates in the correct direction (counterclockwise when looking from the front) If this is not the case, change the setting of your ESC or swap any two of the three cables between the motor and ESC. Fit 32 mm spinner with blades corresponding to your motor and battery set-up.

Recommended control surface throw, CG position

- CG position: 77–81 mm

- Rudder: ±32 deg

- Elevator: +18/-17 deg

- Ailerons: +20/-10 deg, butterfly +25 deg

- Flaps: +20/-10 deg, butterfly -38 deg

Flying

Be sure you are using fully charged batteries. Now (and before any further flight again) check the correct function of the whole radio equipment, motor and moving of control surfaces. Be sure any part of flight equipment cannot move during flight. We strongly recommend making a range check (see your radio instruction manual for details).

The first flight: Wait for a calm day. Fly only on a safe site such as an RC club flying field. Glider will be very happy on your favourite slope on a calm day. The very light lift will allow perfect fine trimming out.

Glider: Switch your transmitter and then the receiver on and check all the working systems one more. Facing INTO the wind hold your transmitter in one hand; grip the model in the other hand near the centre of gravity. Hold it at head level and give the model a fairly powerful push exactly into the wind; wings level, nose slightly down. Your model should now glide in a long, flat and straight path without needing any help from you. Use the controls gently if necessary, and adjust the trim tabs until your Cumul 100 glides above the described way. Now check the position of control surfaces; set the length of pushrods to bring back trim tabs on your transmitter to the central position if necessary (we strongly recommend doing it in any way). Check again the gliding of your Cumul 100.

Now you are ready to make your first bungee launch. Always use a bungee set appropriate to the size (100–150 m) and weight of your model!

Electric version: Switch your transmitter and then the receiver on and check all the working systems once again. Launch your Cumul 100 with a throttle fully open INTO the wind. During climbing be gentle on the controls; try to keep the model flying into the wind until you have about 100–150 metres of altitude. Climb slowly - too steep climbing may cause the model will stall and fall to the ground. You are at 150 metres - this is time to trim out your Cumul 100 at full power. After everything is OK - it means the model at approx. 50–60 % of full throttle flies straight without turning, descending or ascending (if your Cumul 100 already tends to ascend you will have to increase motor down thrust), turn the motor off and test Cumul 100’s gliding characteristics.

Keep your Cumul 100 in the wind and observe its flight. If it turns without power right (although under power it kept the straight direction) it will be necessary to increase the motor's right side thrust and vice versa. If it descends too much without power (although under power it kept the level flight) you will have to increase motor down thrust (assuming the centre of gravity is correct! - check it after landing).

Final fine-tuning: During the next flights trim out your Cumul 100 to find the optimal setting - safe climbing and good gliding - it is a compromise, of course. You might find it useful to program a butterfly/camber → elevator mix (if your radio allows) that will eliminate the nose pitching when the butterfly brake is being deployed or the camber changing flaps/ailerons are being extended. In general, the CG position should be located between 77–81 mm behind the wing leading edge. Moving the CG back improves gliding performance whilst reducing stability. It makes your model more sensitive to controls and increases the model reaction on thermal. The back CG position makes the model more difficult to fly and requires more attention from you, while a nose-heavy model is easier to fly but you will lack the performance. We recommend starting with the CG at 77 mm behind the leading edge. Beyond 81 mm the increasing lack of stability starts to prevail over the gain of gliding performance.

Enjoy your new Cumul 100, have a ball!

Parts list

| Main parts | |||

|---|---|---|---|

| Part | Quantity | Building plan no. | Material |

| Building plan 1:1 | 3 sheets | ||

| Instruction manual | 1 | ||

| Sheet of stickers | 1 | ||

| Pushrod set | 2 | Plastic tube + 0.8 mm piano wire | |

| Tail boom | 1 | F1 | Carbon tube Ø18×10 mm |

| Fuselage | 1 | F3 | Carbon-reinforced fibreglass |

| *Wing centre rib | 2 | W2 | Plywood 0.8 mm |

| *Wing centre shear webbing joiner | 1 | W27 | Plywood 0.8 mm |

| *Wing joiner bay plate - front | 2+2 | W31+W36 | Plywood 0.8 mm |

| *Wing joiner bay plate - rear | 2+2 | W32+W35 | Plywood 0.8 mm |

| Bag no. 1 - small parts | |||

| Adjustable tow hook w. screws | 1 | Fibreglass + metal | |

| Wing bolt M5 | 1 | Steel M5×30 mm | |

| Wing bolt M4 | 1 | Steel M4×20 mm | |

| Horizontal tailplane bolt M4 | 1 | Plastic M4×20 mm | |

| Horizontal tailplane bolt M3 | 1 | Plastic M3×25 mm | |

| Ball link M2 | 2 | Plastic + metal | |

| Quick link | 6 | Plastic | |

| Quick link w. metal pin | 4 | Plastic + metal | |

| Threaded coupler M2 | 4 | Brass M2/0.8 mm | |

| Rudder and elevator horn | 2 | R9, T11 | Fibreglass |

| Aileron horn | 2 | W101 | Fibreglass |

| Flap horn | 2 | W100 | Fibreglass |

| Servo stopper | 3 | F4B, F4C | Fibreglass |

| Rudder and elevator servo tray (glider) | 1 | F4 | |

| Kevlar® thread | 1 | ||

| Wing joiner | 2 | W102 | Carbon |

| Wing alignment pin | 4 | W103 | Aluminium |

| Dihedral jig 7 deg | 1 | Lite Ply 3 mm | |

| Dihedral jig 8 deg | 1 | Lite Ply 3 mm | |

| MPX8 connector | 1 pair | Plastic + metal | |

| Servo cover | 2 pairs | W41 + W42 | Carbon |

| *Pushrod holder | 1+1+1 | 1.2 Plywood | |

| Aileron and flap rod | 2+2 | Carbon Ø 2×58 mm | |

| Bag electric | |||

| Firewall | 1 | F3 | Fibreglass 3 mm |

| Nose cut jig | 1+1 | Lite Ply 3 mm | |

| Rudder and elevator servo tray (electric) | 1 | F4E | Lite Ply 3 mm |

| Bag no. 2 | |||

| Wing joiner bay | 2+2 | W30+W37 | Plywood 5 mm |

| Wing centre section end rib | 2 | W7 | Lite Ply 3 mm |

| Wing outer panel root rib | 2 | W49 | Lite Ply 3 mm |

| Wing centre rib | 2 | W1 | Lite Ply 3 mm |

| Wing bolt plate front | 1 | W15 | Plywood 4 mm |

| Wing bolt plate rear | 1 | W18 | Plywood 4 mm |

| Wing bolt block front | 1 | W16 | Balsa 8 mm |

| Wing bolt block rear | 1 | W17 | Balsa 5 mm |

| Gussets | 2+2 | W47+W48 | Balsa 2.5 mm |

| Bag no. 3 | |||

| Horizontal stabiliser | 1 | T1 | Balsa 4 mm |

| Elevator | 1 | T2 | Balsa 4 mm |

| Horizontal centre block | 1 | T10 | Balsa 4 mm |

| Stabiliser bolt inserts | 1+1 | T8+T9 | Plywood 4 mm |

| Stabiliser cross braces | 2+2+2+2+2 | T3+T4+T5+T6+T7 | Balsa 4 mm |

| Fin | 1 | R1 | Balsa 4 mm |

| Fin cross braces | 1+1+1+1+1 | R3+R4+R5+R6+R7 | Balsa 4 mm |

| Rudder | 1 | R2 | Balsa 4 mm |

| Rudder reinforcement | 1 | R8 | Balsa 4 mm |

| Bag no. 4 | |||

| Tail skid | 1 | F6 | Lite Ply 3 mm |

| Horizontal stabiliser pylon | 1 | F9 | Lite Ply 3 mm |

| Horizontal stabiliser seat | 1 | F10 | Lite Ply 3 mm |

| Pylon side block | 2 | F11 | Balsa 4 mm |

| Captive nut front | 1 | Aluminium M4 | |

| Captive nut rear | 1 | Aluminium M3 | |

| Bag - Wing parts | |||

| Wing centre section leading edge | 1 | W8 | Balsa 8×10×850 mm |

| Wing panel leading edge | 2 | W75 | Balsa 8×10×550 mm |

| Winglet leading edge | 2 | W76 | Balsa 7×8×290 mm |

| Wing centre section main spar | 2 | W9 | Pine 10×2×850 mm |

| Wing centre section rear spar | 1 | W10 | Pine 6×3×850 mm |

| Wing panel main spar | 4 | W77 | Pine 10×2×550 mm |

| Wing panel rear spar | 2 | W78 | Pine 6×3×550 mm |

| Winglet main spar | 4 | W91 | Balsa 8×2×310 mm |

| Winglet rear spar | 2 | W85 | Pine 4×2×250 mm |

| Wing centre section support spar | 1 | W14 | Balsa 3×3×850 mm |

| Wing panel support spar | 2 | W90 | Balsa 3×3×550 mm |

| Wing centre section shear webbing | 2 | W29 | Balsa 5 mm |

| Shear webbing joiner - rear | 1 | W28 | Plywood 0.8 mm |

| Wing panel shear webbing | 2 | W35 | Balsa 5 mm |

| Flap support spar | 2 | W11 | Balsa 5 mm |

| Flap leading edge | 2 | W12 | Balsa 7 mm |

| Aileron support spar | 2 | W79 | Balsa 5 mm |

| Aileron leading edge | 2 | W80 | Balsa 7 mm |

| Wing centre section trailing edge | 1+1 | W13+W19 | Balsa 5 mm |

| Wing panel trailing edge | 1+1 | W81+W83 | Balsa 5 mm |

| Winglet trailing edge | 1+1 | W82+W84 | Balsa 5 mm |

| Wing centre section D-Box sheeting - top | 1 | W39 | Balsa 1.5×50×850 mm |

| Wing centre section D-Box sheeting - bottom | 1 | W38 | Balsa 1.5×15×850 mm |

| Wing panel D-Box sheeting - top | 2 | W89 | Balsa 1.5×50×550 mm |

| Wing panel D-Box sheeting - bottom | 2 | W87 | Balsa 1.5×15×550 mm |

| Winglet D-Box sheeting - top | 2 | W88 | Balsa 1.5×38×250 mm |

| Winglet D-Box sheeting - bottom | 2 | W86 | Balsa 1.5×15×250 mm |

| *Wing centre sheeting | 1+1+1+1+1 | W20a+W20b+W21+W22+W23 | Balsa 2 mm |

| *Wing ribs | 2+2 | W6+W50 | Balsa 7 mm |

| *Wing ribs | 2+2+2+2 | W66+W67+W74+W33 | Balsa 5 mm |

| *Wing ribs and riblets | 6+4+12 | W4+W5+W3 | Balsa 2 mm |

| *Wing panel and winglet ribs | 8 pairs | W52+W54+W56+W58+W60+W62+W64+W69 | Balsa 2 mm |

| *Winglet ribs and wing panel riblets | 9 pairs | W71+W73+W51+W53+W55+W59+W61+W63+W65 | Balsa 2 mm |

| **Aileron and flap servo tray | 2+2 | W26+W45 | Lite Ply 3 mm |

| **Flap servo bay sheeting | 2 | W24 | Balsa 2.5 mm |

| **Aileron servo bay sheeting | 2 | W44 | Balsa 2.5 mm |

| **Flap and aileron horn block | 2+2 | W25+W46 | Balsa 8 mm |

| **Wingtip | 2 | W43 | Balsa 3 mm |

| **MPX8 connector holder | 1 | W40 | Plywood 0.8 mm |

*) Sheet w. CNC cut parts

**) Small bag w. parts