KAVAN Cumul DLG kit 1096mm - Instruction manual

Introduction

Precautions

This RC model is not a toy. Use it with care and strictly following the instructions in this manual.

Assemble this model following strictly these instructions. DO NOT modify or alter the model. Failure to do so, the warranty will lapse automatically. Follow the instructions to obtain a safe and solid model at the end of the assembly.

Children under the age of 14 must operate the model under the supervision of an adult.

Assure that the model is in perfect condition before every flight, taking care that all the equipment works correctly and that the model is undamaged in its structure.

Fly only on days with a light breeze and in a safe place away from any obstacles.

You must build the model according to the instructions. Do not alter or modify the model, as doing so may result in an unsafe or unflyable model. Take time to build straight, true and strong. Use proper radio and other equipment that is in first-class condition, properly install all the components and test their correct operation before the first and any further flight. Fly the model only with competent help from a well-experienced modeller if you are not already an experienced RC pilot.

Specification

| Wingspan: | 1096 mm |

| Length: | 880 mm |

| All-up weight: | 180 g |

| Wing section: | YA 0801 |

| CG position: | 65–70 mm |

| Controls: | Rudder, elevator |

Recommended RC equipment

- Rudder and elevator servo: KAVAN GO-6MG 2×

- Receiver battery: 1S LiPo 3.7 V 450–500 mAh

Recommended glues

Unless stated otherwise, use medium cyanoacrylate (CA) glue (KAV9952 KAVAN CA Medium). Wing sheeting is better to be glued using a water-resistant white aliphatic resin, like our KAV9960 KAVAN White Glue (alternatively, you can use this sort of glue for most of the wood-to-wood joints). The highly loaded parts (wing roots, fuselage formers etc.) should be glued together using 30-minute (or slower) epoxy (like KAV9967 Epoxy 30 min) offering high strength and enough time for the correct positioning.

Tools and accessories

- Very sharp modeller’s knife (e.g. Excel 16001 with no.11 blades)

- Scissors

- Electric drill with drill bits

- Wire cutter

- Long nose pliers

- Screwdrivers

- Razor saw

- Sandpaper no.100–120, 180–220, 360–400

- Needle files

- Soldering iron and solder

- Clothing pegs

- Modeller’s pins

- Epoxy mixing stick and vessel

- Masking tape, clear sticky tape

- Rubbing alcohol (for cleaning up excessive epoxy)

- Paper tissue or soft cloth (for cleaning up excessive epoxy)

- Straightedge with scale

- Square edge

- Thin clear plastic film (for protecting the building plan)

- Permanent marker

- Modeller’s sealing iron, heat gun (for covering)

- Lightweight balsa filler

- Hot melt glue gun & hot melt glue

It is your responsibility, and yours alone, to build this model correctly, properly install RC equipment and motor and test the model and fly in accordance with all safety standards (and common sense) as set down in Safety Codes valid in your country.

If you are just starting RC modelling, consult your local hobby shop or an experienced modeller in your local RC club to find a good instructor.

Model assembly

Tail surfaces

- Trial fit the parts of the horizontal stabilizer, elevator, fin and rudder – no glue yet! Sand as necessary to obtain a perfect fit. (Fig. 1+2)

- Roughen the surface of the 3×0.5 mm R3 carbon spar using no.120 sandpaper and glue it with medium CA to the trailing edge of the fin R1.

- Glue the T3 reinforcement plate into the horizontal stabilizer T1. Once the glue has cured, sand it flush with the stabilizer.

- Sand the entire surface of the horizontal stabilizer, elevator, fin and rudder with no.120–150 sandpaper; round the outer edges.

- Put the tail surfaces aside for now. They will be finished after the tailplane seat is installed to the tail boom.

Fuselage

- Trial fit the parts of the fuselage – no glue yet! Sand as necessary to obtain a perfect fit. Be sure the tail boom F1 could be inserted easily but tightly into the openings in F10 and F8 formers. (Fig. 1+3)

- Glue the balsa reinforcement plate F2L to the inner side of the F3L fuselage left side (with the large opening for the F11 hatch); glue the plate F2R to the inner side of the F3R fuselage right side (without the hatch opening). (Fig. 3)

- Glue the F14 locking plate to the front of the F11 hatch; the locking plate has to match the position of a notch in the F2L reinforcement plate and the hatch matches the opening in the F3L fuselage side. The pair of F15 magnets will be epoxied into the F11 hatch and F2L plate only after the fuselage is covered – otherwise the high temperature of your sealing iron might demagnetize the magnets. (Fig. 22)

- Epoxy the M4 aluminium captive nut into the F9 fuselage brace. Do not forget bevelling the edges of the fuselage formers and braces where required.

- Epoxy the fuselage formers and braces F10, F9, F8, F6 first into one fuselage side from the rear to the nose and then attach the other side. Put the fuselage straight bottom side onto the building plan protected by a sheet of thin clear plastic film and check the fuselage is true and straight - pin down as necessary until the glue sets. (Fig. 5)

- Epoxy the F4 former in place and bevelled F5 nose balsa block as well as the F17 and F18 cross braces.

- Epoxy the tow hook plate F7 in place. (Fig. 6)

- Partially cut (ca 0.5–1 mm deep) and crack the fuselage sides along the F10 fuselage former (the cut line is to be soaked with thin CA before the final sanding). Slide the tail boom tube F1 onto the openings in F8 and F10 formers – do not glue yet.

- Slide the F21 Lite Ply tail boom fairing ring onto the tail boom F1; tack glue the fuselage sides to the ring (be sure not to glue the tail boom yet). Glue the top and bottom balsa plates F20 and F19 in place. (Fig. 7)

- Glue the three-piece upper F13a, F13b, F13C and F16 lower 2.5 mm balsa sheeting to the fuselage.

- Sand the entire fuselage (with the F11 hatch in place) so the tail end including the F21 ring fits smoothly in the tail boom.

Wing

- The wing is to be built directly on the building plan protected by a sheet of thin clear plastic film. The wing ribs and riblets are supplied with jig tabs on the bottom side to allow building the wing with under cambered profile on a flat surface; at the same time producing the washout (the wing trailing edge is higher by 3 mm at the tips than at the root) necessary for stable flight of the model. DO NOT CUT the mounting jigs; they will be removed only after the entire wing has been built. There is also the rib spacing jig to set the leading edge ends of rib and riblet mounting jigs correctly. (Fig. 1 + 9 + 10)

- Epoxy together the wing central ribs W4 and W5; insert 3 mm beech dowels into the holes to obtain a correct match. Note: Make a left and right pair of assemblies.

- Glue together the wing tip W28 with the plywood reinforcement plate W40 to the trailing edge W30 on a flat working surface; glue the W26 and W27 reinforcement plates in place creating a notch for the plywood wing tip spar W29. (Fig. 11+12)

- Thread all the wing ribs and riblets W3 to W24 onto the main spar carbon tube W35; use a round file to trim the openings in the ribs to set the ribs in the required angle. (Fig. 10)

- Put the main spar with ribs onto the building plan and insert the ends of ribs into the corresponding notches in the trailing edge W30. Insert the front ends of the rib jig tabs into the corresponding notches of the rib spacing jig. Align all the parts to the correct position over the building plan; pin down where necessary, and then glue the ribs W4 to W23 to the main spar tube and the trailing edge. Epoxy the wing tip spar W29 into the main spar tube and to the wing tip into the notch between the W26 and W27 reinforcement plates. Glue the wing tip to the W24 rib and finally the W24 rib to the main spar and trailing edge. Glue the balsa gusset W25 between the W24 rib and W23 riblet.

- Glue the root rib W3 using the root rib dihedral jig in place. (Fig. 13)

- Trim the notches for the leading edge W36 (3 mm beech dowel) in the ribs and riblets as necessary. Glue the leading edge (starting from the wing tip and then rib by rib towards the wing root). (Fig. 14)

- Epoxy the plywood wing joiner bay plates W33 into the W3 and W4/W5 ribs - be sure the bay will accommodate the W34 wing joiner nicely. (Fig. 15)

- Now you can carefully cut the rib jig tabs using a sharp modeller’s knife. Sand the bottom side of all ribs and riblets to shape with no.120 sandpaper.

- Glue the bottom wing centre 1.5 mm balsa sheeting W39 and W40 in place; glue the plywood reinforcement plate W41 on the top of W40 along the area of the wing fixing bolt. (Fig. 16)

- Glue the top wing centre 1.5 mm balsa sheeting W37 and W38 in place. Sand the wing root flush with the W3 rib - the slanted position set with the root rib dihedral jig ensures the correct wing dihedral.

- Assemble the other wing half in the same way.

- Sand both two wing halves with no.120 sandpaper. Trial fit - no glue yet - the wing halves and the W34 wing joiner; insert the riblets W1 and W2 between the root ribs. Once satisfied with the fit, epoxy the W34 wing joiner, W1 and W2 riblets to one wing half. Then slide on and epoxy the other half. Double-check the correct wing halves alignment and let the epoxy set. (Fig 17+23+24)

- Epoxy the wing bolt plate W32 to the top of the wing centre; once the glue has cured, drill a 4.2mm hole for the wing bolt through the W32.

- Now it is the time to decide which tip of the wing the discus launch pin is to be glued into - the left tip for a right-handed pilot, the right tip for a left-handed pilot. Laminate a strip of the fibreglass cloth around the hole for the discus launch pin on top and bottom of the wing tip. You can use a special low-viscosity laminating/finishing epoxy or you can use regular epoxy glue thinned slightly by an epoxy paint/dope thinner. Once the resin has cured, sand the entire wing smooth with no.180 sandpaper.

Covering

- Thoroughly sand the surface of all parts with no.360–400 sandpaper and carefully vacuum all the dust (the iron-on film does not stick well to a dusty surface; the dust also contains hard grains released off the sandpaper capable of ruining the smooth coating of your sealing iron quickly).

- Use as light iron-on film as you can get (transparent Oracover, Oralite etc. – not supplied in the kit). Follow the instruction manual supplied with the covering film of your choice please.

Final assembly

Hinging the control surfaces

- Use strips of high-quality hinging tape (available in hobby shops) or strips of the same iron-on film you used for the covering. Remember to apply the tape with the control surface deflected to the limit to get free movement of the particular control surface. (Fig. 19)

Fuselage and tail

- Using a very sharp pointed modeller’s knife, cut the covering film over the opening for the tailplane pylon in the horizontal stabilizer, over slots for the Kevlar® thread in the fin and over the control horn slots in the elevator and rudder.

- Insert the tailplane pylon F22 into the F1 tail boom - no glue yet. Insert the fin and rudder assembly into the notch at the end of the tail boom and tack glue it to the tail boom. Bind the fin to the tail boom with a Kevlar® thread threaded through the slots in the fin.

- Slide the horizontal stabilizer on the F22 tailplane pylon; align it square to the fin and to the longitudinal axis of the tail boom and tack glue it to the pylon. Double-check the correct alignment; once satisfied, apply a generous amount of cyano along all the joints and onto the Kevlar® thread. Insert the elevator and rudder push rod outer tubes into the tail boom. Secure them with a piece of polyurethane foam soaked with epoxy that you will work into the centre of the tail boom with a thin stick. This is great for a precise, slope free elevator and rudder control. (Fig. 20 + 21)

- The F12 servo mount supplied in the kit has been tailored for the recommended KAVAN GO-6MG servos. If you go for a different type of servos, the openings might need a bit of trimming. We recommend soaking the edges of the servo openings with cyano. Once satisfied, glue the F12 servo mount in place (the servos are to be fitted in the upside-down position). (Fig. 22)

- Thread the protruding ends of the elevator and rudder push rod outer tubes through the holes in the F6 former so the tubes lead directly to the horns of servos in the F12 servo mount. Insert the tail boom into the fuselage - no glue yet.

- Attach the wing to the fuselage and secure it with the M4 bolt. Looking from above, front and rear check the fuselage and tail boom are straight and the wing dihedral makes a nice symmetrical "V" in relation to the horizontal stabilizer. Once satisfied cut the push rod outer tubes to the correct length and epoxy thoroughly the tail boom into the fuselage. Double-check the correct alignment before the glue sets.

- Solder the M2 brass threaded couplers on one end of the 0.8 mm piano wire push rods. Screw the ball links on and slide the push rods into the respective outer tubes. Secure the ball links to both two servo arms with the M1.6 screws supplied in the kit. Insert the fibreglass control horns into the slots in the elevator and rudder - do not glue yet. Set the servos to the neutral with your radio on; attach the servo arms square to the side of the servo case. Set the elevator and rudder flush with the horizontal stabilizer resp. fin. Mark the correct length of the push rods and bend them to the right angle (you can make a "Z-bend", but the simple L-bend usually works well enough). Insert the L-bends into the holes in the control horns and cyano the horns into the elevator and the rudder still set in the neutral position. Finally, secure the servos with drops of hot melt glue, silicone or MS polymer glue in the servo tray. (Fig 20 + 21 + 22)

- Install your received into the fuselage under the wing, the receiver battery will go into the nose. (Fig. 18+22)

Wing

- Epoxy thoroughly the carbon discus launch pin into the left (for a right-handed pilot) or right (for a left-handed pilot) wing tip. (Fig. 25)

Tow hook

- Install the tow hook into one of the pre-drilled holes in the F7 tow hook plate. It should be positioned about 5 mm in front of the centre of gravity.

Recommended control surface throw, CG position

- CG Position: 69–72 mm

- Rudder: ± 25 mm

- Elevator: ± 10 mm

- Discus launch configuration: rudder -1 mm against the direction of the launch (right-handed - rudder 1 mm right), elevator 1 mm down.

Flying

Be sure you are using fully charged batteries. Now (and before any further flight again) check the correct function of the whole radio equipment, motor and moving of control surfaces. Be sure any part of flight equipment cannot move during flight. We strongly recommend making a range check (see your radio instruction manual for details).

The first flight: Wait for a calm day. Fly only on a safe site such as an RC club flying field. Glider will be very happy on your favourite slope on a calm day. The very light lift will allow perfect fine trimming out.

Switch your transmitter and then the receiver on and check all the working systems one more time. Facing INTO the wind hold your transmitter in one hand; grip the model in the other hand near the centre of gravity. Hold it at head level and give the model a fairly powerful push exactly into the wind; wings level, nose slightly down. Your model should now glide in a long, flat and straight path without needing any help from you. Use the controls gently if necessary, and adjust the trim tabs until your CUMUL DLG glides above the described way. Now check the position of control surfaces; set the length of pushrods to bring back trim tabs on your transmitter to a central position if necessary (we strongly recommend doing it in any way). Check again the gliding of your CUMUL DLG.

Now you are ready to make your first discus launch.

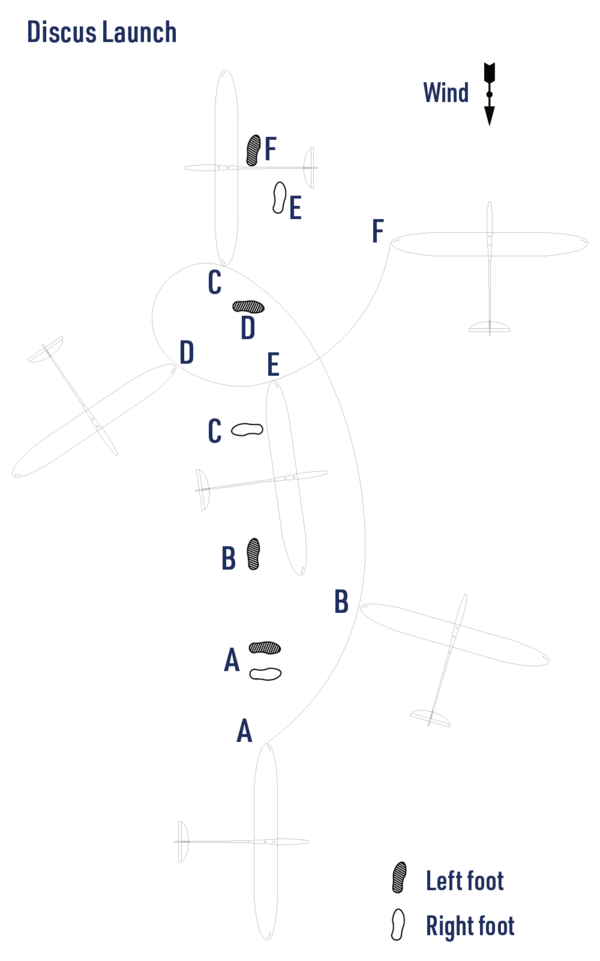

Discus Launch

The discus launch allows your model to reach a quite high altitude without much effort. As it is with any "sports performance", it will require some training to do it right – our step-by-step manual makes it easy. We will describe the procedure for a right-handed pilot; with the launching pin attached to the left wingtip. The "left-handed" procedure is the mirror image.

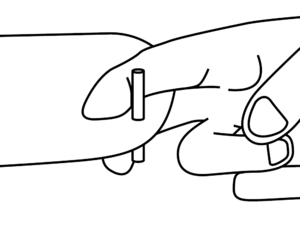

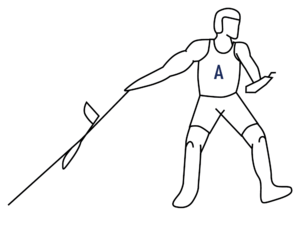

Position A - getting ready:

Your right index finger and middle finger should be wrapped around the launch pin at the left wing tip. Your thumb is to be gently pressed against the leading edge of the wing. Stand with your left shoulder into the wind and the right wing tip pointing at ca 45° angle to the ground.

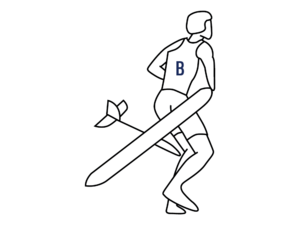

Position B - the first step:

Take a long step with your left foot pulling the CUMUL DLG up and forward with your right arm.

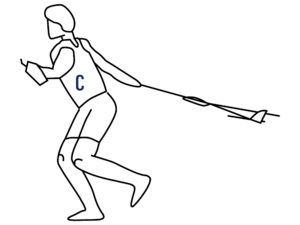

Position C - rotation:

Start rotating to the left keeping the CUMUL DLG flat and your right arm extended.

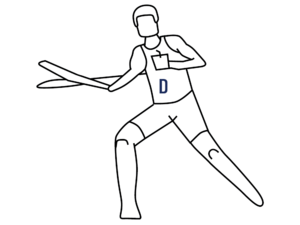

Position D - continued rotation:

The second half of the rotation - the part that is most important for a good launch. Do not use too much arm in this section. Just let the swing of your torso speed the CUMUL DLG up.

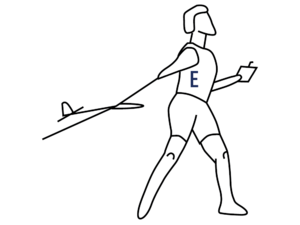

Position E - release:

By this time in the launch the plane will be trying to climb on its own. Just release your fingers and let the plane fly out of your hand directly into the wind.

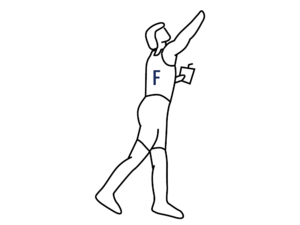

Position F - taking control:

Catch your balance. Watch your CUMUL DLG climb whilst getting hold of your radio and be ready to control your model. The plane will climb after release – the climb angle should be shallow at first. Once you are well acquainted with the discus launch you can use more force and increase the launch angle up to 60–80 degrees. When completely familiar and comfortable you can add two quick steps before starting the turning sequence to get some extra speed and energy.

When the plane has slowed almost to the point of stopping push full down elevator to achieve level flight. When this is done at the right moment the plane will go into horizontal flight with just enough airspeed to maintain a gentle glide. If it is done too early the plane will pitch up her nose dangerously after a short dive. If it is done too late the plane will stall.

Parts list

| Main parts | |||

|---|---|---|---|

| Part | Quantity | Building plan no. | Material |

| Building plan 1:1 | 1 | ||

| Instruction manual | 1 | ||

| Sheet of stickers | 1 | ||

| Pushrod set | 2 | Plastic tube + 0.8 mm piano wire | |

| Tail boom | 1 | F1 | Carbon tube Ø6/5 mm |

| Bag no. 1 - small parts | |||

| Tow hook | 1 | Metal | |

| Magnet Ø3 mm | 2 | F15 | Neodymium |

| Wing bolt M4 | 1 | Nylon | |

| Captive nut M4 | 1 | Aluminium | |

| Rudder horn | 2 | Fibreglass 1.5 mm | |

| Ball link short M2 | 2 | ||

| Threaded coupler M2 | 2 | Brass 0.8 mm | |

| Rudder and elevator servo tray | 1 | F12 | Balsa 4 mm |

| Carbon pin | 1 | Ø5 mm | |

| Fibreglass cloth | 1 | 110 g/m² | |

| Bag no. 2 | |||

| Nose block | 1 | F5 | Balsa 10 mm |

| Servo hatch | 1 | F11 | Plywood 1.2 mm |

| Fuselage former | 1 | F6 | Plywood 3 mm |

| Fuselage formers | 1+1+1 | F4, F8, F10 | Lite Ply 3 mm |

| Fuselage cross-brace | 1+1 | F17, F18 | Lite Ply 3 mm |

| Fuselage hatch lock | 1 | F14 | Lite Ply 3 mm |

| Tail boom fairing ring | 2 | F21 | Lite Ply 3 mm |

| Wing riblet | 1 | W2 | Lite Ply 3 mm |

| Root rib dihedral jig | 1 | Lite Ply 3 mm | |

| Nose shape template | 1 | Lite Ply 3 mm | |

| Bag no. 3 | |||

| Wing rib | 2 | W4 | Plywood 0.8 mm |

| Wing centre sheeting reinforcement | 2 | W41 | Plywood 0.8 mm |

| Wing joiner bay plate | 4 | W33 | Plywood 0.8 mm |

| Towhook plate | 1 | F7 | Plywood 2 mm |

| Wing captive nut brace | 1 | F9 | Plywood 2 mm |

| Wing bolt plate | 1 | W32 | Plywood 2 mm |

| Wing tip spar | 2 | W29 | Plywood 2 mm |

| Wing riblet | 1 | W1 | Plywood 3 mm |

| Wing joiner | 1 | W34 | Plywood 3 mm |

| Wing tip reinforcement plate | 2 | W40 | Plywood 1.5 mm |

| Bag no. 4 - tail | |||

| Horizontal stabilizer | 1 | T1 | Balsa 2.5 mm |

| Elevator | 1 | T2 | Balsa 2.5 mm |

| Horizontal stabilizer reinforcement plate | 1 | T3 | Balsa 2.5 mm |

| Fin | 1 | R1 | Balsa 2.5 mm |

| Rudder | 1 | R2 | Balsa 2.5 mm |

| Carbon fin reinforcement | 1 | R3 | Carbon 0.5×3 mm |

| Tailplane pylon | 1 | F22 | Lite Ply 3 mm |

| Kevlar thread | 1 | ||

| Bag no. 5 | |||

| Wing rib | 2 | W6, 8, 10, 12 | Balsa 1.5 mm |

| Wing riblet | 2 | W7, 9, 11, 13–23 | Balsa 1.5 mm |

| Wing root rib | 2 | W3 | Balsa 4 mm |

| Wing tip rib | 2 | W24 | Balsa 4 mm |

| Wing rib | 2 | W4 | Balsa 3 mm |

| Trailing edge | 1+1 | W30, W31 | Balsa 3×15 mm |

| Leading edge | 2 | W36 | Beech dowel Ø3 mm |

| Wing tip reinforcement plate | 2+2 | W26,W27 | Balsa 1.5 mm |

| Wing tip | 2 | W28 | Balsa 1.5 mm |

| Gusset | 2 | W25 | Balsa 1.5 mm |

| Wing main spar | 2 | W35 | Carbon tube Ø6/5 mm |

| Wing centre sheeting | 2+2+2+2 | W37, W38, W39, W40 | Balsa 1.5 mm |

| Bag no. 6 | |||

| Fuselage side | 1+1 | F2L/R | Balsa 1.5 mm |

| Fuselage bottom sheeting | 1 | F16 | Balsa 2.5 mm |

| Fuselage upper sheeting | 1+1+1 | F13a, b, c | Balsa 2.5 mm |

| Fuselage side reinforcement plate | 1+1 | F2L/R | Balsa 3 mm |

| Tail boom fairing | 1+1 | F19, F20 | Balsa 2.5 mm |